Tillverkningsfabrik för whiskyglas

DM Glassware tillverkar ett brett sortiment av whiskyglas i flera år. Från design, prototyping, custom, produktion, ytdekoration, vi är experter på detta område.

Anpassade whiskyglas

Whiskyglas används för att dricka whisky, bourbon och scotch. De är också en typ av whiskyglas. De är mycket välkomnade av människor över hela världen.

Vår produktkatalog innehåller en hel del heta modeller. Från rund form, fyrkantig form till med/utan mönster. De bästa whiskyglasen är med kristallmönster. De kan också kallas gammaldags whiskyglas eller vintage whiskyglas.

DM glasdesign och produktion personliga whiskyglas i många år. Vi kan anpassa mönstren för bästa njutning. För att ange din egen varumärkeseffekt kan vi göra din logotyp med laser på botten. Dessutom är unika packboxar ett måste för dessa unika whiskyglas.

DM är ett whiskyglas leverantör i Kina. Har du några projekt inom detta område hittar du alla lösningar hos DM.

Välj från vår whiskyglaskatalog

DM331-serien

Funktioner hos våra whiskyglas

Vitt och klart

Vårt råmaterial är högvitt sodalimeglas. Med speciell sammansättning är våra glasögon rent vita och transparenta. De är precis som diamanter.

Produktvariation

Vi tillhandahåller ett brett utbud av whiskyglas för att tillgodose olika kunders preferenser, vilket säkerställer att du har allt du behöver under ett tak.

Kvalitetskontroll

Vårt QC-team fortsätter att övervaka hela produktionen och se till att varje bit whiskyglas är bra.

Design och anpassad

Våra innovativa design och anpassningsalternativ, inklusive logodekaler, gravering och målning, hjälper dig att skapa unika produkter som speglar ditt varumärke.

Applikationsscenarier för whiskyglas

Barer och restauranger

Förbättra presentationen av premium whisky, bourbon och scotch, och erbjuda kunderna en raffinerad dryckesupplevelse.

Hembruk

Perfekt för personlig njutning eller för att underhålla gäster, våra whiskyglas ger en touch av sofistikering till alla hemmabarer.

Företagspresenter

Anpassningsbara whiskyglas är utmärkta företagspresenter och marknadsför ditt varumärke med graverade logotyper eller personlig design.

Vilka material används för att göra whiskyglas?

Högvitt Soda Lime Glas

Soda-kalciumglas, även känd som soda-lime silikatglas, är sammansatt av följande råvaror:

Kiseldioxid (SiO2): från kvartssand, en av huvudkomponenterna i glas, vilket ger det hårdhet och kemisk stabilitet.

Kalciumoxid (CaO): från kalksten (CaCO3) eller kalcit (CaO), vilket hjälper till att justera glasets smältpunkt och kemiska egenskaper.

Natriumoxid (Na2O): från soda (Na2CO3), vilket sänker glasets smältpunkt och ökar dess plasticitet.

Dessa ingredienser blandas samman efter exakt vägning och genomgår en högtemperatursmältningsprocess för att bilda en homogen glasvätska.

Under formningsprocessen blåses den smälta glasvätskan in i formen och olika former av glasprodukter erhålls genom att kontrollera mängden blåsning och formen på formen. Efter formning måste glasprodukterna glödgas för att avlägsna inre spänningar och förbättra styrkan och stabiliteten.

Det här är vår råvaruverkstad.

Vad är tillverkningsprocessen för whiskyglas?

Som huvud produktionsprocessen för glasgjutning har pressformning blivit en av de mest effektiva formningsprocesserna för glasprodukter på grund av dess snabba, effektiva och exakta egenskaper.

Vid formpressning värms råvaror som sand, kalk och soda först upp och smälts i en ugn vid grader Celsius för att producera flytande glas. Efter homogenisering och rening lagras det smälta glaset i en tömningscylinder.

Detta är produktionsprocessen för brandpolering för att göra glasprodukten slät och platt.

Tillverkningstekniker

Under formningen extruderas det smälta glaset och stympas för att bilda en massa glasdroppar.

Glasdropparna matas sedan in i en lågtemperaturform, som fylls med tryckluft eller kolvtryck, kyls och får härda helt innan de tas ur formen och sugs ut.

Efter att glaskoppen tagits ut är munnen relativt platt, men det kan bli grader om den inte hanteras väl, vilket kräver en bakmun, som placeras på bakmaskinen och bränner glaskoppens mynning med eld (koppen placeras på bakmaskinen och roterar), så att glasgraderna smälts två gånger, vilket gör glaskoppens mynning väldigt platt.

Sedan, glasprodukten in i glasglödgningsugnen glödgning, vilket eliminerar den interna spänningen av glaset (inte efter glödgning glaset är lätt att spricka), och slutligen, från glödgning ugnen ut ur glaset är den vanliga glas färdiga koppen.

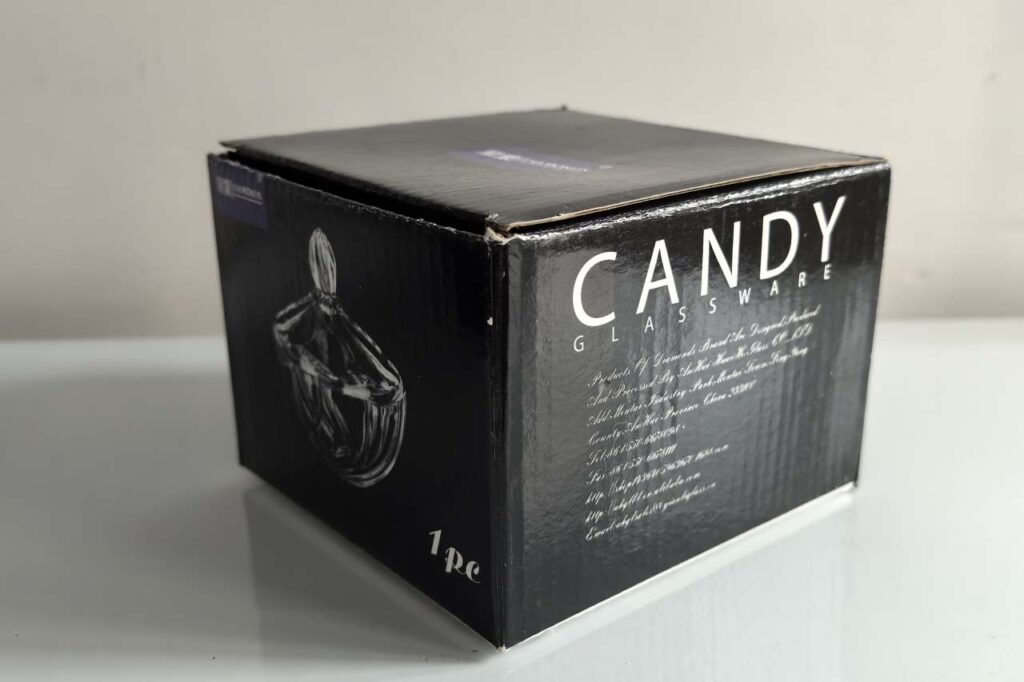

Förpackningsalternativ för whiskyglas

Individuell boxförpackning

- Beskrivning: Varje whiskyglas är förpackat i sin egen robusta låda för maximalt skydd.

- Bäst för: High-end, lyxiga whiskyglas eller presenter.

- Fördelar: Lägger till en premiumkänsla och säkerställer att glaset förblir säkert under frakt eller förvaring.

Ställ in förpackning

- Beskrivning: Flera whiskyglas packas tillsammans i en enda låda, vanligtvis i set om 2, 4 eller 6.

- Bäst för: Återförsäljare eller kunder som köper set för hemmabruk eller presenter.

- Fördelar: Ekonomisk och effektiv, perfekt för presentset eller massbeställningar.

Märkesförpackning

- Beskrivning: Förpackningar anpassade med din logotyp, varumärkesfärger eller design.

- Bäst för: Företag som strävar efter att öka varumärkets synlighet genom förpackningar.

- Fördelar: Erbjuder en personlig touch och gör uppackningsupplevelsen mer minnesvärd för kunderna.

Anpassade alternativ

Logo dekal är en mycket vanlig glasbehandlingsprocess för att få ditt varumärke att sticka ut. Det är billigt och visar en mängd olika färger.

Brotthastigheten är också mycket låg under operationen. Dekaler kan väljas från miljövänliga typer som uppfyller livsmedelssäkerhetscertifieringar.

Detta är laser eller sandblästringsprocess, en process som visar produktens logotyp genom att förstöra ytan på glaset.

Denna typ av logotyp är berörbar för hand och mycket strukturerad. För whiskyglas med mönstrad yta kan vi gravera på botten av glaset.

Att anpassa storleken och finishen på ett whiskyglas kräver en viss startordning. Med skräddarsydda formar kan du producera exklusiva produktformer och mönster, samt varumärkeslogotyper.

Kostnaden för att anpassa produkten skulle bara vara den extra kostnaden för formen, men det är väl värt det för varumärket.

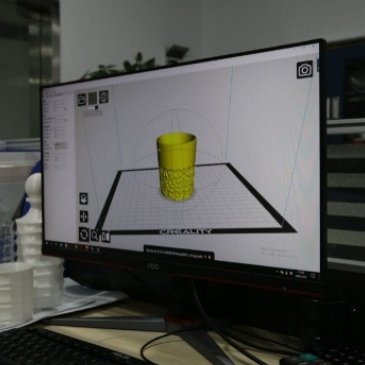

Produktionsprocess

3D-modellering

3D-fotokopiering

Gravyr för hand

Laser med logotyp

Vanliga frågor om whiskyglas

Ledtiden för produktionen varierar beroende på olika tillfällen. Om du vill köpa från våra lager kan vi göra leverans inom 3 dagar. För specialbeställningar tar det vanligtvis 40-45 dagar för produktion efter orderbekräftelse.

För våra lager börjar 1 kartong med våra förpackningar.

För anpassade glasögon finns det två olika situationer:

1- Du behöver våra klara glaskoppar med dina egna logotyper eller dekorationer, MOQ är 10000 st. Du kan få ytterkartongen med dina egna fraktmärken.

2- För att producera dina anpassade mönster och göra nya lister kommer MOQ att vara 80k – 100k st.

För glaskoppsprov är det gratis. Du behöver bara betala expresskostnad eller tillhandahålla ditt kurirkonto.

Om du vill göra ett logotypprov eller dekorerat ett, är provtagningskostnaden USD50-USD100.

För att anpassa nya glasögon med annan form, tack kolla med vårt team.

Ja, absolut. Du kan komma på besök när som helst.

Vi erbjuder olika typer av whiskyglas inklusive rocksglas och highballglas.

Ja, vi erbjuder anpassningsalternativ som logotypdekaler, gravering och målning för att anpassa dina whiskyglasögon.

Ja, vi erbjuder konkurrenskraftiga priser och rabatter för massbeställningar. Behaga kontakta vårt säljteam för en detaljerad offert.

Ja, våra whiskyglas tål maskindisk. Vi rekommenderar dock handtvätt för skräddarsydda och graverade glasögon för att bevara designen.

Relaterade inlägg

Skräddarsydda tjänster för tillverkning av whiskyglasögon

10+ års erfarenhet. Olika glasdesigner. Professionellt FoU-team. Konkurrenskraftigt pris.