Custom Glass Shot Glasses In Bulk Supply

Shot glasses are small glasses used to drink strong drinks like spirits and liqueurs in little amounts. Most shot glasses hold around 1.25 oz. to 1.5 oz (1 oz=28.35ml).

As a glassware manufacturer in China, DM Glassware is producing and supplying different styles of shot glasses. Every piece of unique shot glass is produced through advanced machine-manufacturing processes to ensure the highest standards of quality and consistency.

DM Glassware offers a diverse selection of shot glasses, including various sizes, shapes, and decorative designs, such as logo decals, painting, etching, engraving, and printing, catering to different customer needs. With processing, you can have your own branded shot glasses.

If you are looking for a reliable shot glass company and even a partner, you can rely on DM. Buy shot glasses in bulk from us and let us help you grow your business using our customization and affordable products.

Shot Measurements

Use this handy guide to make sure your cocktail recipes are perfectly measured and your shots are on point!

Single Shot: 1.5 oz = 3 tablespoons = 9 teaspoons = 44 mL

Double Shot: 3 oz = 6 tablespoons = 18 teaspoons = 88 mL

Quality Shot Glasses to Increase Sales

DM Glassware is a well-known shot glasses manufacturer with a lot of experience. Our team works hard to make high-quality shot glasses that meet different needs.

We have a wide range of shot glasses, from small 1.5 oz sizes (about 44 ml) to bigger ones. These glasses come in many styles, from old-fashioned to modern, and can have decorations like logos, paintings, engravings, and prints. This variety helps us appeal to many customers.

Our shot glasses are great for both casual parties and formal events, offering both practicality and style. By focusing on excellent quality, DM Glassware meets customer needs and keeps a strong position in the market.

Shot Glass Size

The standard shot glass size is 1.5oz. There are also larger and smaller versions for the shot glasses, ranging from 1.5oz to 3oz We support our clients to customize the volume depending on specific requirements.

Shot Glass Color

We supply shot glasses in transparent. If you need them in colors, we could make painting on them. With food safe paints, you can have any colors with the Pantone Code. Also, mixed colors are also workable on one item.

Engraved Shot Glasses

Engraving is one popular processing option to have your logo on the shots. Usually we make this by laser or sand-blasting. We offer a high-tech laser engraving process that provides detailed and precise decorations.

Shot Glass Design

We can custom unique shot glass by moulding. You can customize each glass with your business logo engraved in moulds. The logo will be prominently displayed on the glass, making it visible while in use.

What size is a whiskey shot glass?

A standard whiskey shot glass typically holds 1.5 ounces (44 milliliters) of liquid, which is the common shot size in the United States. However, whiskey shot glasses can vary slightly depending on their style and the country. For example:

- Double Shot Glasses: Hold 2 to 3 ounces (59 to 89 milliliters), ideal for larger pours.

- European Standard: May hold 1 to 1.25 ounces (30 to 37 milliliters).

Always check the specific shot glass to ensure it matches your desired measurement.

How Many mL in a Shot Glass?

A 1.5 oz. shot is equivalent to 44 milliliters (mL). While this is the standard shot size in the U.S., shot glasses can vary in size depending on the type. You can find shot glasses that hold anywhere from 28 mL (for smaller shots) up to 90 mL (for double shots or large shooters). Always be sure to check the size of your shot glass to ensure you’re serving the correct amount for your drink recipe or desired serving.

How Many Ounces Are In A Double-Shot Glass?

A double-shot glass typically holds 2 to 3 ounces of liquid.

- In most cases, a double shot is exactly 2 ounces (59 milliliters).

- Some double-shot glasses may be slightly larger, accommodating up to 3 ounces (89 milliliters), depending on regional standards or design.

This capacity is twice the size of a standard shot glass, which holds 1.5 ounces in the United States. Always check the specific glass to ensure it matches your needs, especially for precise cocktail measurements.

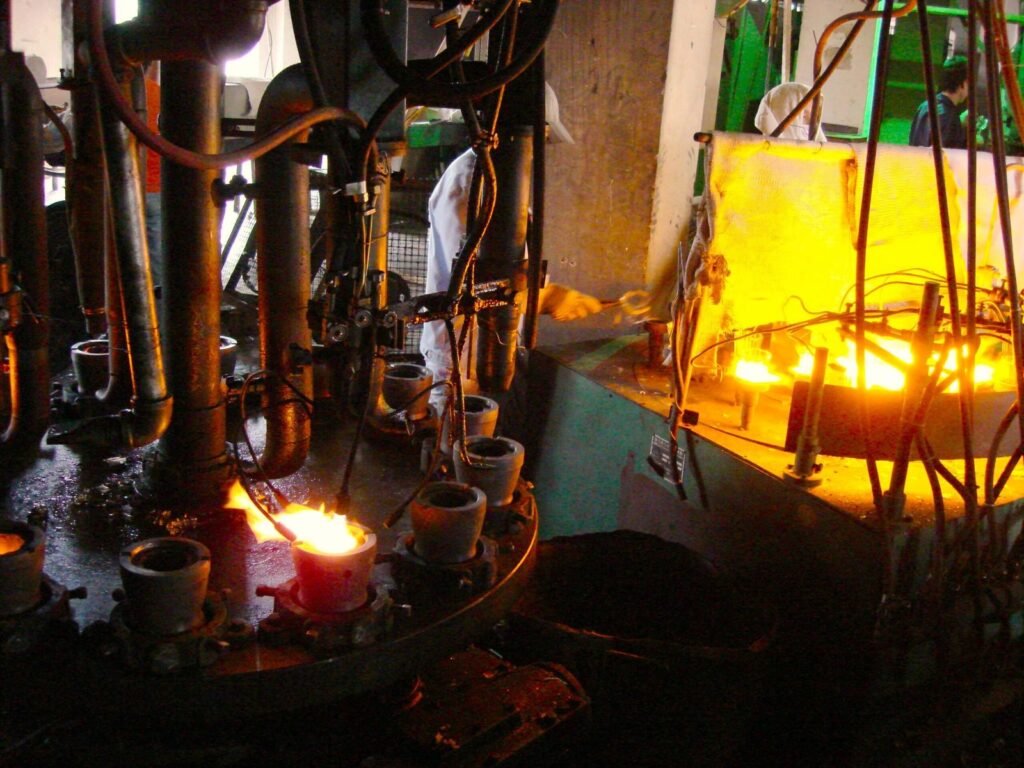

Glassware Manufacturing

Our mechanized production process uses state-of-the-art machinery to create bar glasses with consistent quality and precise dimensions.

This method is ideal for large-scale production, ensuring quick turnaround times and competitive pricing. Perfect for businesses requiring bulk orders with uniform designs.

What materials are used to make shot glasses?

High-white Soda Lime Glass

Soda-calcium glass, also known as soda-lime silicate glass, is composed of the following raw materials:

Silicon dioxide (SiO2): from quartz sand, one of the main components of glass, giving it hardness and chemical stability.

Calcium oxide (CaO): from limestone (CaCO3) or calcite (CaO), which helps to adjust the melting point and chemical properties of the glass.

Sodium oxide (Na2O): from soda ash (Na2CO3), which lowers the melting point of the glass and increases its plasticity.

These ingredients are mixed together after precise weighing and undergo a high-temperature melting process to form a homogeneous glass liquid.

During the molding process, the molten glass liquid is blown into the mold, and various shapes of glass products are obtained by controlling the amount of blowing and the shape of the mold. After molding, the glass products need to be annealed to remove internal stresses and improve strength and stability.

This is our raw material workshop.

What is the manufacturing process for shot glasses?

As the main production process for glass molding, press molding has become one of the most effective molding processes for glass products due to its fast, efficient and precise characteristics.

In compression molding, raw materials such as sand, lime and soda are first heated and melted in a furnace at degrees Celsius to produce liquid glass. After homogenization and purification, the molten glass is stored in a discharge cylinder.

This is the production process of fire polishing to make the glass product smooth and flat.

Manufacturing Techniques

During forming, the molten glass is extruded and truncated to form a mass of glass droplets.

The glass droplets are then fed into a low-temperature mold, which is filled with compressed air or plunger pressure, cooled and allowed to fully cure before being removed from the mold and sucked out.

After the glass cup is taken out, the mouth is relatively flat, but there may be burrs if it is not handled well, which requires a baking mouth, which is placed on the baking machine and burns the mouth of the glass cup with a fire (the cup is placed on the baking machine and is rotating), so that the glass burrs are melted twice, thus making the mouth of the glass cup very flat.

Then, the glass product into the glass annealing furnace annealing, eliminating the internal stress of the glass (not after annealing the glass is easy to burst), and finally, from the annealing furnace out of the glass is the usual glass finished cup.

Features Of Our Shot Glasses

Smooth Rim and Heavy Bottom

Various Decorations

Custom Options

Logo decal is very common glass finishing process to make your brand stand out. It is inexpensive and displays a variety of colors.

The breakage rate is also very low during the operation. Decals can be chosen from environmentally friendly types that meet food safety certifications.

This is the laser or sandblasting process, a process that displays the product logo by destroying the surface of the glass.

This kind of logo is touchable by hand and very textured. For whiskey glasses with patterned surface, we can engrave on the bottom of the glass.

Customizing the size and finish of a whiskey glass requires a certain starting order. With custom molds, you can produce exclusive product shapes and patterns, as well as brand logos.

The cost of customizing the product would just be the added cost of the mold, but it’s well worth it for the branding.

Order Process

DM makes ordering easy and efficient with a clear process from start to finish.

Submit Inquiry

Share your product requirements, specifications, and customization needs with our team.

Receive Quote

Get a detailed proposal and competitive pricing tailored to your needs.

Sample Approval

Review and approve product samples to ensure satisfaction before production.

Shipping

Products are packed securely and shipped to your destination on time.

Quality Inspection

Each product undergoes rigorous testing to meet international standards.

Production

Our team manufactures your products with strict quality control measures.

FAQ

The lead time for production varies depending on different occasions. If you want to buy from our stocks, we can make the delivery in 3 days. For custom orders, it usually takes 40-45 days for production after order confirmation.

For our stocks, 1 carton starts with our packagings.

For custom glasses, there are two different situations:

1- You need our clear glass cups with your own logos or decorations, MOQ is 10000pcs. You can have the outer carton with your own shipping marks.

2- To produce your custom designs and make new mouldings, the MOQ will be 80k – 100k pcs.

For clear glass cup sample, it’s free of charge. You only need to pay express cost or provide your courier account.

If you want to make a logo sample or decorated one, the sampling cost is USD50-USD100.

For customizing new glasses with different shape, please check with our team.

Yes, for sure. You can come to visit anytime.

1.5oz normally.

It’s soda lime glass, food safe.

Yes for sure. Please send us your design.

Related Posts

Get A Solution On Your Shot Glasses Project

We are ensuring the quality of every piece of glass cup, on-time delivery and on-budget.