Glass Decal Customization: Durable Branding for Your Drinkware

Introduction

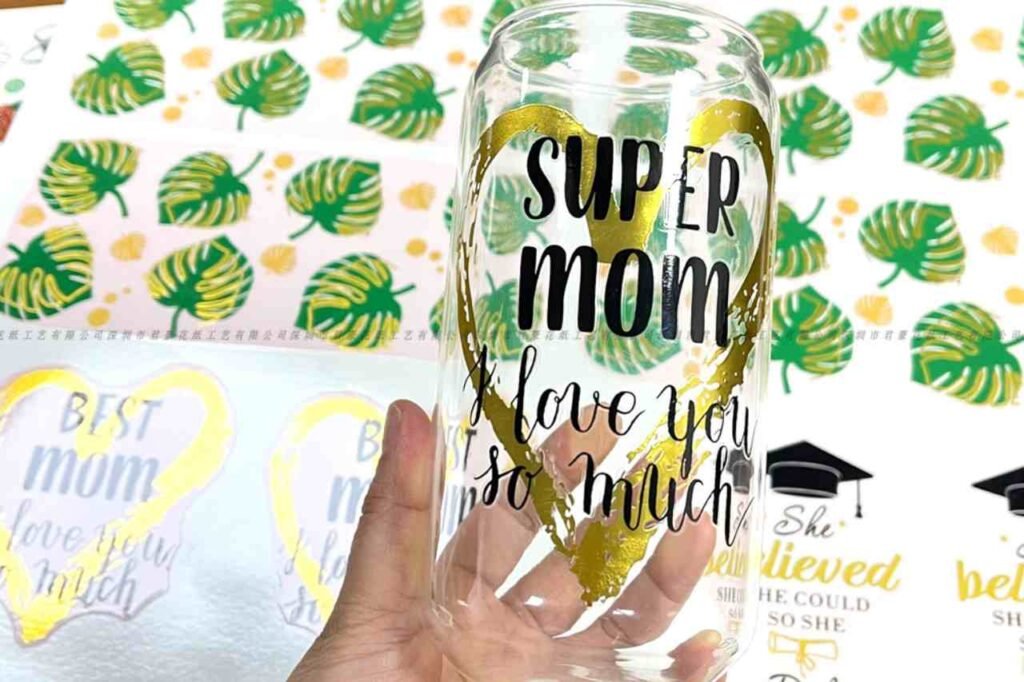

How Glass Decals Work: Materials & Process

Decal Paper: The Base

Ceramic Inks: The Color

Colors and Customization

Understanding Ceramic Colors

Getting the Right Colors

Applying the Decal: From Design to Finished Glass Cup

Design and Artwork Preparation

Printing the Decal

Putting it on the Glass

Firing: The Final Step

Quality and Durability: What Makes a Good Decal?

Adhesion and Permanence

Common Problems and Fixes

DM Glassware: Your Partner for Custom Decals

Our Promise of Quality

Why Choose DM Glassware for Your Decal Logos?

Conclusion

Frequently Asked Questions About Custom Glassware With Decal Logo

What is glass decal customization?

Glass decal customization is the process of adding logos, artwork, or text to glassware using printed ceramic decals. These decals are applied to the surface of the glass and then permanently fused through high-temperature firing. The result is a durable, vibrant design that looks like part of the glass itself.

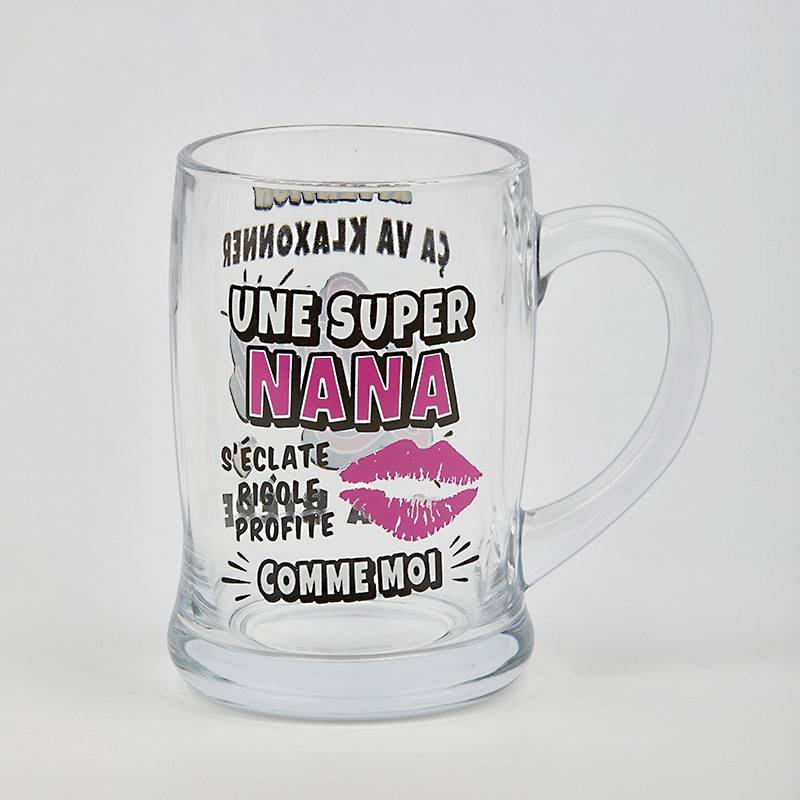

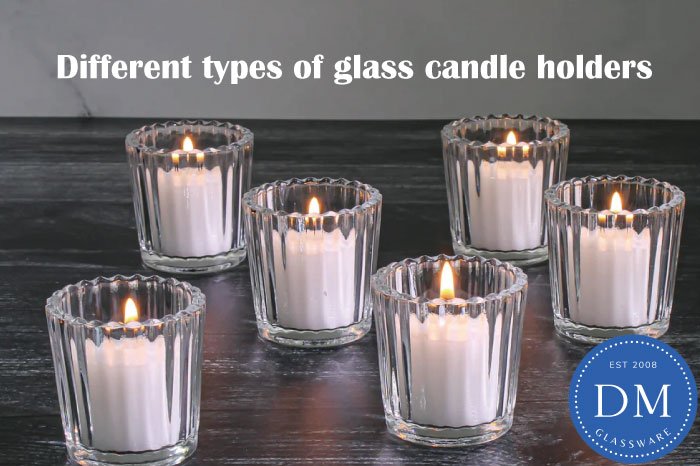

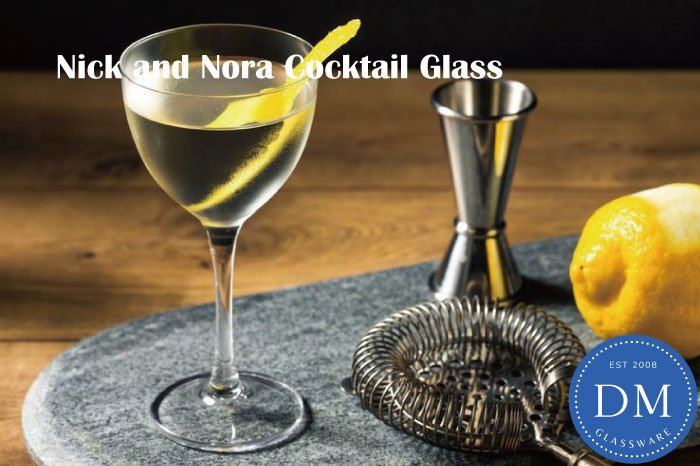

Can I add my logo to cocktail or wine glasses?

Yes! We can apply your custom logo or design to almost any type of glassware, including cocktail glasses, wine glasses, beer mugs, tumblers, and more. It’s a great way to create branded drinkware for bars, restaurants, events, or promotional use.

Do you offer full-color decals on barware?

Absolutely. We offer multi-color and full-color decal printing using heat-stable ceramic pigments. While neon or fluorescent colors aren’t possible due to firing limitations, we can closely match Pantone shades and create detailed, colorful designs.

How durable are customized glass decals?

Very durable. Once fired, the decal becomes a permanent part of the glass, making it resistant to scratches, fading, and washing. Our decals are designed to withstand daily use, including in busy commercial settings like bars and restaurants.

What’s the MOQ for custom glassware with decals?

Our typical minimum order quantity (MOQ) starts at 5000 pieces per design, but this can vary depending on the glass type and complexity of the artwork. Contact us for details and bulk pricing.

Are custom decal glasses dishwasher safe?

Yes. Our properly fired decal glasses are dishwasher safe, even in commercial dishwashers. The colors won’t fade or peel when cared for correctly.

Where can I order branded glassware in bulk with decals?

You can order directly from DM Glassware, a leading manufacturer specializing in custom glassware decoration. We offer bulk pricing, fast production, and expert support from design to delivery.

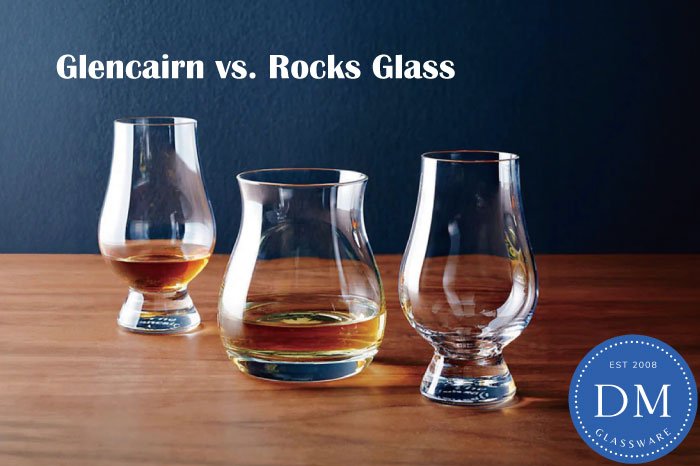

What’s the difference between etched and decal glass customization?

Etched glass is created by sandblasting or acid-etching the surface, producing a frosted, single-color effect. Decals, on the other hand, allow for full-color, detailed graphics and branding. Decals are ideal if you want logos, text, or multi-color designs that stand out visually.

Can I design custom seasonal decals for drinkware?

Yes! We can help you create limited-edition or seasonal designs for holidays, events, or promotions. Whether it’s for Christmas, summer specials, or corporate campaigns, our team can assist with artwork, layout, and production.

How long does it take to produce personalized decal glasses?

Production time usually takes 2–4 weeks, depending on order size, design complexity, and current capacity. We also offer sample approvals before full production begins to ensure you’re happy with the final result.