ഗ്ലാസിന് ലേസർ കൊത്തുപണിയുടെ സമഗ്രമായ ഗൈഡ്

നിങ്ങളുടെ ബൾക്ക് ഗ്ലാസ്വെയർ പ്രോജക്റ്റിനായി തനതായ ടച്ച് എങ്ങനെ ചേർക്കാമെന്ന് എപ്പോഴെങ്കിലും ചിന്തിച്ചിട്ടുണ്ടോ?

അങ്ങനെയാണെങ്കിൽ, ഈ ഗൈഡ് നിങ്ങൾക്ക് ഒരു നല്ല പരിഹാരം വാഗ്ദാനം ചെയ്യും.

നിങ്ങൾ അറിയേണ്ടതെല്ലാം ഇതിൽ അടങ്ങിയിരിക്കുന്നു ഗ്ലാസിൽ ലേസർ കൊത്തുപണി.

ഉള്ളടക്ക പട്ടിക

ഗ്ലാസിന് ലേസർ കൊത്തുപണി എന്താണ്?

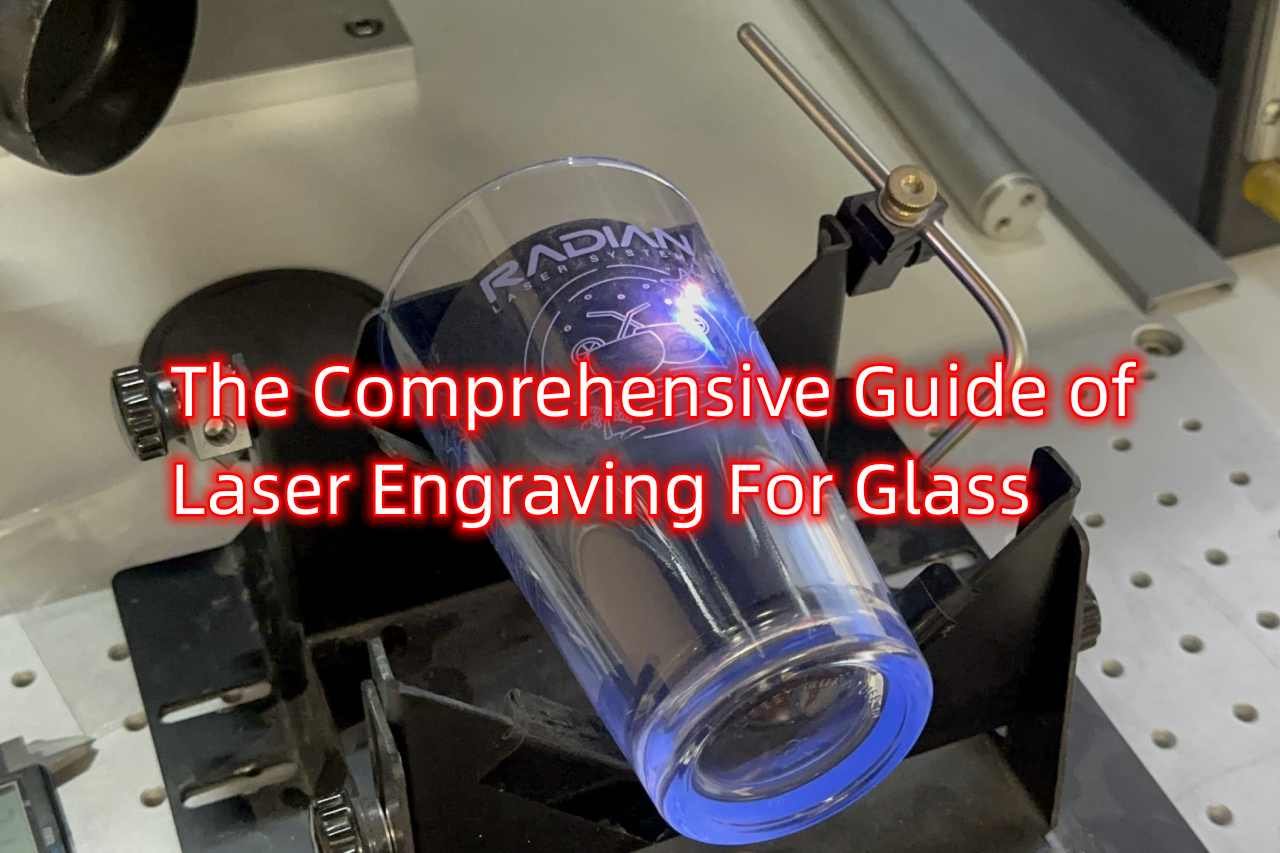

ഗ്ലാസിന് ലേസർ കൊത്തുപണി

ഗ്ലാസിൻ്റെ ഉപരിതലത്തിൽ ഡിസൈനുകൾ, പാറ്റേണുകൾ, ലോഗോകൾ അല്ലെങ്കിൽ ടെക്സ്റ്റ് എന്നിവ കൊത്തിവയ്ക്കുന്നതിന് ഫോക്കസ് ചെയ്ത പ്രകാശം ഉപയോഗിക്കുന്ന ഒരു പ്രക്രിയയാണ് ലേസർ കൊത്തുപണി. ഇത് ഒരുതരം ഉപരിതല സംസ്കരണമാണ് ഗ്ലാസ്വെയർ നിർമ്മാണം.

ഫോക്കസ്ഡ് ബീം ഉപയോഗിച്ചുള്ള ഈ പ്രക്രിയ ഗ്ലാസിൻ്റെ ഉപരിതല പാളി നീക്കം ചെയ്യുന്നു, ഗ്ലാസിൽ ശാശ്വതവും വിശദവുമായ അടയാളം സൃഷ്ടിക്കുന്നു.

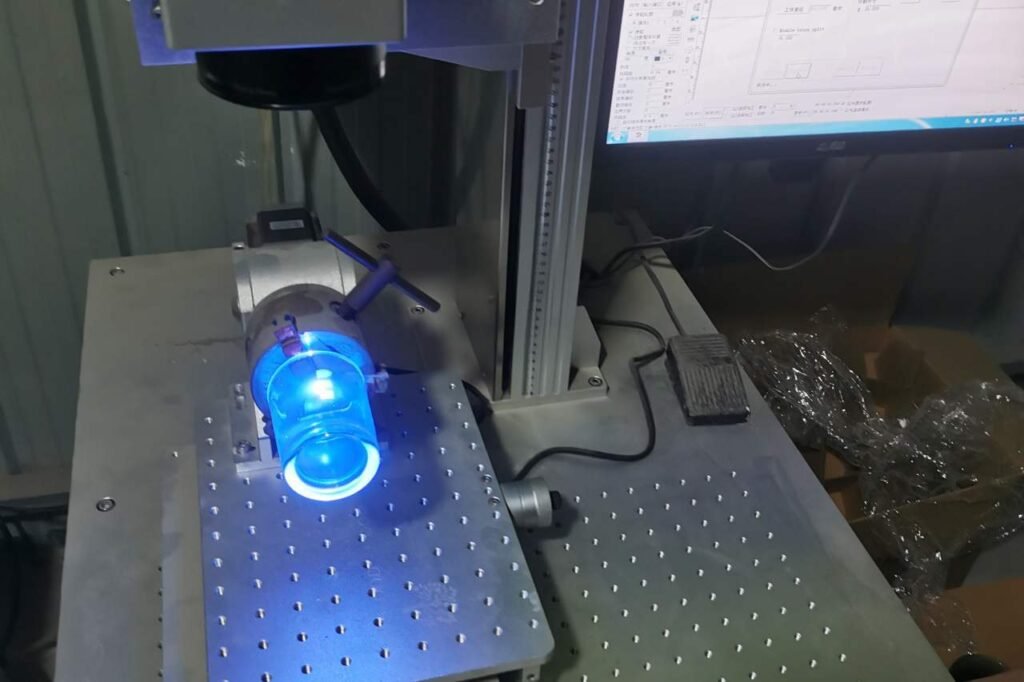

ഗ്ലാസ് പ്രക്രിയയ്ക്കായി ലേസർ കൊത്തുപണി

ഗ്ലാസിനുള്ള ലേസർ കൊത്തുപണികൾ കൃത്യവും സങ്കീർണ്ണവുമായ ഒരു പ്രക്രിയയാണ്, ഇത് കമ്പ്യൂട്ടർ നിയന്ത്രിക്കുന്നു.

കമ്പ്യൂട്ടർ നിയന്ത്രണം: മുഴുവൻ പ്രവർത്തനത്തെയും നിയന്ത്രിക്കുന്ന ഒരു കമ്പ്യൂട്ടർ പ്രോഗ്രാം ഉപയോഗിച്ചാണ് ലേസർ കൊത്തുപണി പ്രക്രിയ ആരംഭിക്കുന്നത്. ഈ പ്രോഗ്രാം പലപ്പോഴും ഒരു കമ്പ്യൂട്ടർ-എയ്ഡഡ് ഡിസൈൻ (CAD) ഫയലാണ്, അത് ഗ്ലാസിൽ കൊത്തിവയ്ക്കേണ്ട ഡിസൈൻ, ലോഗോ അല്ലെങ്കിൽ ടെക്സ്റ്റ് എന്നിവയെ പ്രതിപാദിക്കുന്നു.

ലേസർ ബീം ജനറേഷൻ: ഉയർന്ന തീവ്രതയുള്ള ലേസർ ബീം സൃഷ്ടിക്കപ്പെടുന്നു. ഈ ബീം ഫോട്ടോണുകൾ ചേർന്നതാണ്, സാധാരണയായി 0.1 മുതൽ 0.2 മില്ലിമീറ്റർ വരെ വീതിയുണ്ട്. ഇത് ഗണ്യമായ അളവിൽ ഊർജ്ജം വഹിക്കുന്നു, സാധാരണയായി 30 മുതൽ 100 വാട്ട് വരെ, ഗ്ലാസ് കൊത്തുപണിക്ക് മതിയാകും.

ബീം ദിശ: തന്ത്രപ്രധാന സ്ഥാനങ്ങളിൽ സ്ഥാപിച്ചിരിക്കുന്ന കണ്ണാടികളുടെ ഒരു പരമ്പര ഉപയോഗിച്ച് ഗ്ലാസ് പ്രതലത്തിലേക്ക് ലേസർ ബീം നയിക്കപ്പെടുന്നു. ഈ കണ്ണാടികൾ ഗ്ലാസിൽ ആവശ്യമുള്ള കൊത്തുപണി സ്ഥലത്തേക്ക് ബീമിനെ കൃത്യമായി നയിക്കുന്നു.

ബീം ഫോക്കസ് ചെയ്യുന്നു: ഉയർന്ന നിലവാരമുള്ള ലെൻസ് ഗ്ലാസ് പ്രതലത്തിലെ ഒരു ചെറിയ സ്ഥലത്തേക്ക് തീവ്രമായ ബീമിനെ കേന്ദ്രീകരിക്കുന്നു. ഈ ഫോക്കസ്ഡ് സ്പോട്ട് നിർണായകമാണ്, കാരണം ഇത് കൊത്തുപണിയുടെ കൃത്യതയും വ്യക്തതയും നിർണ്ണയിക്കുന്നു.

മെറ്റീരിയൽ ഇടപെടൽ: ഫോക്കസ് ചെയ്ത ലേസർ ബീം ഗ്ലാസിൽ പതിക്കുമ്പോൾ, അത് മെറ്റീരിയലിനെ വളരെ ഉയർന്ന താപനിലയിലേക്ക് ചൂടാക്കുന്നു. ഈ തീവ്രമായ ചൂട് നിയന്ത്രിത രീതിയിൽ ഗ്ലാസ് പൊട്ടുകയോ പൊട്ടുകയോ ബാഷ്പീകരിക്കപ്പെടുകയോ ചെയ്യുന്നു. ലോഹങ്ങളിൽ നിന്ന് വ്യത്യസ്തമായി, ഗ്ലാസ് ഉരുകുന്നില്ല, പകരം "മൈക്രോ ഫ്രാക്ചറിംഗ്" എന്ന പ്രക്രിയയ്ക്ക് വിധേയമാകുന്നു, അവിടെ കൊത്തുപണി സൃഷ്ടിക്കുന്നതിന് ഉപരിതലത്തിൽ ചെറിയ വിള്ളലുകൾ രൂപം കൊള്ളുന്നു.

കൊത്തുപണി പ്രക്രിയ: CAD ഡിസൈൻ സജ്ജീകരിച്ചിരിക്കുന്ന നിയുക്ത പാതയിലൂടെ ലേസർ നീങ്ങുമ്പോൾ, അത് ഗ്ലാസിനെ തകർക്കുന്നത് തുടരുന്നു, ആവശ്യമുള്ള പാറ്റേൺ അല്ലെങ്കിൽ വാചകം രൂപപ്പെടുത്തുന്നു. ഈ പ്രക്രിയ നോൺ-കോൺടാക്റ്റ് ആണ്, അതായത് ലേസർ ഗ്ലാസിൽ ശാരീരികമായി സ്പർശിക്കുന്നില്ല, ഇത് മെറ്റീരിയലിന് കേടുപാടുകൾ വരുത്താനുള്ള സാധ്യത കുറയ്ക്കുന്നു.

കൃത്യതയും വിശദാംശങ്ങളും: ലേസർ ബീം നിയന്ത്രിക്കാൻ കഴിയുന്ന കൃത്യത കാരണം ലേസർ കൊത്തുപണിക്കാരന് വളരെ വിശദമായതും സങ്കീർണ്ണവുമായ ഡിസൈനുകൾ സൃഷ്ടിക്കാൻ കഴിയും. ലോഗോകൾ, സങ്കീർണ്ണമായ പാറ്റേണുകൾ, ചെറിയ വാചകങ്ങൾ എന്നിവയ്ക്ക് അനുയോജ്യമാക്കുന്ന, മികച്ച വിശദാംശങ്ങൾ കൊത്തിവയ്ക്കാൻ ഇത് അനുവദിക്കുന്നു.

അന്തിമ ഫലം: കൊത്തുപണി പൂർത്തിയായിക്കഴിഞ്ഞാൽ, സ്ഫടിക പ്രതലത്തിന് ശാശ്വതവും തണുത്തുറഞ്ഞതുമായ രൂപം ഉണ്ടാകും, അവിടെ ലേസർ ഡിസൈൻ കൊത്തിവച്ചിരിക്കുന്നു. ഈ ഫ്രോസ്റ്റഡ് ലുക്ക് സൗന്ദര്യാത്മകവും മോടിയുള്ളതുമാണ്, കാലക്രമേണ ഡിസൈൻ മങ്ങില്ലെന്ന് ഉറപ്പാക്കുന്നു.

ചുവടെയുള്ള വീഡിയോ നോക്കുക:

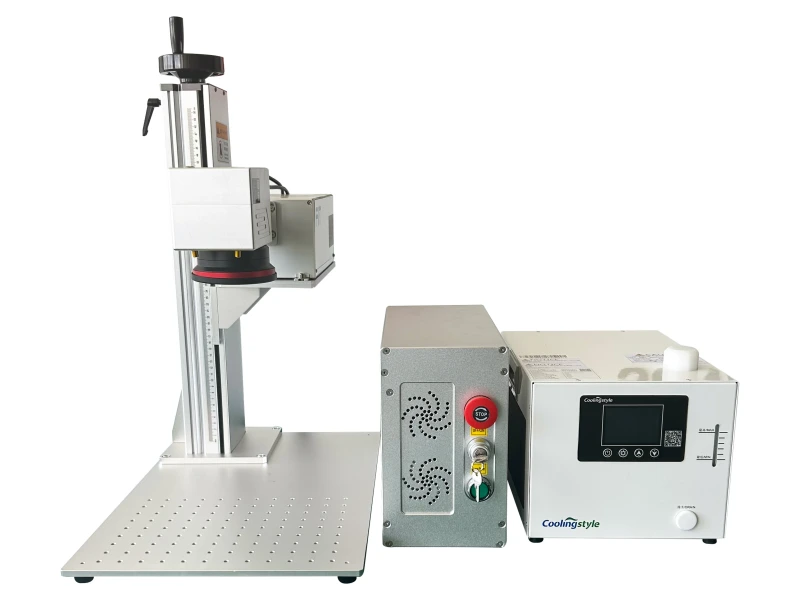

ഗ്ലാസിൽ ലേസർ കൊത്തുപണികൾക്കുള്ള ലേസർ മെഷീനുകളുടെ തരങ്ങൾ

ഗ്ലാസ് ലേസർ കൊത്തുപണികൾക്കായി നിങ്ങൾക്ക് ഒരു ലേസർ മെഷീൻ വാങ്ങണമെങ്കിൽ തിരഞ്ഞെടുക്കാൻ നിരവധി ഓപ്ഷനുകൾ ഉണ്ട്:

CO2 ലേസർ കൊത്തുപണി യന്ത്രങ്ങൾ

വിവരണം: ഗ്ലാസ് കൊത്തുപണികൾക്കായി ഏറ്റവും സാധാരണയായി ഉപയോഗിക്കുന്ന ലേസറുകളാണ് CO2 ലേസറുകൾ. അവർ ഒരു വാതക മിശ്രിതം, പ്രാഥമികമായി കാർബൺ ഡൈ ഓക്സൈഡ്, ലേസിംഗ് മീഡിയമായി ഉപയോഗിക്കുന്നു.

പ്രയോജനങ്ങൾ:

- ബഹുമുഖത: ഗ്ലാസ്, മരം, അക്രിലിക് എന്നിവയും അതിലേറെയും ഉൾപ്പെടെ വിവിധ വസ്തുക്കളിൽ കൊത്തിവയ്ക്കാൻ കഴിയും.

- കൃത്യത: സൂക്ഷ്മവും വിശദവുമായ കൊത്തുപണികൾ നിർമ്മിക്കുന്നു.

- ചെലവ് കുറഞ്ഞതാണ്: മറ്റ് തരത്തിലുള്ള ലേസറുകളെ അപേക്ഷിച്ച് പൊതുവെ ചെലവ് കുറവാണ്.

അപേക്ഷകൾ: കുടിവെള്ള ഗ്ലാസുകൾ, മഗ്ഗുകൾ, അലങ്കാര വസ്തുക്കൾ എന്നിവ പോലുള്ള സങ്കീർണ്ണമായ ഡിസൈനുകൾ, ലോഗോകൾ, ടെക്സ്റ്റ് എന്നിവ ഗ്ലാസ്വെയറിൽ കൊത്തിവയ്ക്കാൻ അനുയോജ്യം.

CO2 ലേസർ എൻഗ്രേവിംഗ് മെഷീനുകൾ ഉപയോഗിച്ച് സ്റ്റെംലെസ് വൈൻ ഗ്ലാസുകൾ എങ്ങനെ കൊത്തിവയ്ക്കാമെന്ന് കാണിക്കുന്ന മറ്റൊരു വീഡിയോ ഇതാ.

ഫൈബർ ലേസർ കൊത്തുപണി യന്ത്രങ്ങൾ

വിവരണം: ഫൈബർ ലേസറുകൾ ലേസിംഗ് മീഡിയമായി അപൂർവ-എർത്ത് മൂലകങ്ങൾ അടങ്ങിയ ഒപ്റ്റിക്കൽ ഫൈബറുകൾ ഉപയോഗിക്കുന്നു. അവ പ്രാഥമികമായി ലോഹങ്ങൾ അടയാളപ്പെടുത്തുന്നതിന് ഉപയോഗിക്കുന്നു, എന്നാൽ ശരിയായ ക്രമീകരണങ്ങളുള്ള ഗ്ലാസ് കൊത്തുപണികൾക്കും ഉപയോഗിക്കാം.

പ്രയോജനങ്ങൾ:

- ഉയർന്ന കാര്യക്ഷമത: CO2 ലേസറുകളേക്കാൾ കാര്യക്ഷമമായി വൈദ്യുതോർജ്ജത്തെ ലേസർ പ്രകാശമാക്കി മാറ്റുന്നു.

- ഈട്: ദൈർഘ്യമേറിയ ആയുസ്സും കുറഞ്ഞ പരിപാലന ആവശ്യകതകളും.

- വേഗത: ചില ആപ്ലിക്കേഷനുകൾക്കായി വേഗത്തിലുള്ള കൊത്തുപണി വേഗത.

അപേക്ഷകൾ: ഗ്ലാസിൽ ചെറുതും സങ്കീർണ്ണവുമായ ഡിസൈനുകൾ അടയാളപ്പെടുത്തുന്നതിന് അനുയോജ്യം, പലപ്പോഴും മറ്റ് വസ്തുക്കളുമായി സംയോജിച്ച് ഉപയോഗിക്കുന്നു.

യുവി ലേസർ കൊത്തുപണി യന്ത്രങ്ങൾ

വിവരണം: UV ലേസറുകൾ ഒരു ചെറിയ തരംഗദൈർഘ്യത്തിൽ പ്രവർത്തിക്കുന്നു (സാധാരണയായി ഏകദേശം 355 nm), ഇത് വളരെ സൂക്ഷ്മവും കൃത്യവുമായ കൊത്തുപണികൾ നിർമ്മിക്കാൻ അനുവദിക്കുന്നു. അവ സാധാരണയായി ഉപയോഗിക്കുന്നില്ലെങ്കിലും ചില ആപ്ലിക്കേഷനുകൾക്ക് വളരെ ഫലപ്രദമാണ്.

പ്രയോജനങ്ങൾ:

- ഉയർന്ന കൃത്യത: വളരെ വിശദവും വൃത്തിയുള്ളതുമായ കൊത്തുപണികൾ നിർമ്മിക്കാൻ കഴിവുള്ള.

- കുറഞ്ഞ ചൂട് ആഘാതം: കുറഞ്ഞ ചൂട് ഉൽപ്പാദനം, അതിലോലമായ ഗ്ലാസ് പ്രതലങ്ങൾക്ക് കേടുപാടുകൾ വരുത്താനുള്ള സാധ്യത കുറയ്ക്കുന്നു.

- ബഹുമുഖത: ഗ്ലാസ്, പ്ലാസ്റ്റിക്, സെറാമിക്സ് എന്നിവയുൾപ്പെടെ വിവിധ വസ്തുക്കളിൽ കൊത്തിവയ്ക്കാൻ കഴിയും.

അപേക്ഷകൾ: ഉയർന്ന നിലവാരമുള്ള ഗ്ലാസ്വെയറിൽ സങ്കീർണ്ണമായ പാറ്റേണുകൾ, ചെറിയ ടെക്സ്റ്റ്, അതിലോലമായ ഡിസൈനുകൾ എന്നിവ പോലുള്ള സൂക്ഷ്മമായ വിശദാംശങ്ങൾ കൊത്തിവയ്ക്കാൻ അനുയോജ്യമാണ്.

നിങ്ങളുടെ ആവശ്യങ്ങൾക്ക് ശരിയായ ലേസർ മെഷീൻ തിരഞ്ഞെടുക്കുന്നു

ലേസർ മെഷീൻ്റെ തിരഞ്ഞെടുപ്പ് ഗ്ലാസിൻ്റെ തരം, രൂപകൽപ്പനയുടെ സങ്കീർണ്ണത, ഉൽപ്പാദന അളവ്, ബജറ്റ് എന്നിവ ഉൾപ്പെടെ വിവിധ ഘടകങ്ങളെ ആശ്രയിച്ചിരിക്കുന്നു. തിരഞ്ഞെടുക്കാൻ നിങ്ങളെ സഹായിക്കുന്നതിനുള്ള ഒരു ദ്രുത ഗൈഡ് ഇതാ:

- ഉയർന്ന വോളിയം ഉൽപ്പാദനത്തിനായി: CO2 ലേസർ മെഷീനുകൾ അവയുടെ ചെലവ്-ഫലപ്രാപ്തിയും വൈവിധ്യവും കാരണം പൊതുവെ ഏറ്റവും മികച്ച തിരഞ്ഞെടുപ്പാണ്. ഗ്ലാസ്വെയറുകളുടെ വലിയ ബാച്ചുകൾ കാര്യക്ഷമമായി കൈകാര്യം ചെയ്യാൻ അവർക്ക് കഴിയും.

- വിശദവും സങ്കീർണ്ണവുമായ ഡിസൈനുകൾക്കായി: അൾട്രാവയലറ്റ് ലേസറുകൾ കൊത്തുപണികളിൽ ഉയർന്ന കൃത്യതയും വ്യക്തതയും കൈവരിക്കുന്നതിന് അനുയോജ്യമാണ്, അവ വിശദമായ കലാസൃഷ്ടികൾക്കും ചെറിയ വാചകങ്ങൾക്കും അനുയോജ്യമാക്കുന്നു.

- മൾട്ടി-മെറ്റീരിയൽ ആപ്ലിക്കേഷനുകൾക്കായി: നിങ്ങളുടെ ഉൽപ്പാദന പ്രക്രിയയിൽ വഴക്കം നൽകിക്കൊണ്ട് ഗ്ലാസിലും ലോഹങ്ങൾ പോലുള്ള മറ്റ് വസ്തുക്കളിലും കൊത്തിവയ്ക്കണമെങ്കിൽ ഫൈബർ ലേസറുകൾ ഒരു നല്ല ഓപ്ഷനാണ്.

ലേസർ എൻഗ്രേവർ

ലേസർ കൊത്തുപണിയുടെ പ്രയോജനങ്ങൾ

- ഉയർന്ന കൃത്യതയും വിശദാംശങ്ങളും: ലേസർ കൊത്തുപണികൾ പരമ്പരാഗത കൊത്തുപണി രീതികൾ ഉപയോഗിച്ച് നേടാൻ പ്രയാസമുള്ള വളരെ സൂക്ഷ്മവും സങ്കീർണ്ണവുമായ വിശദാംശങ്ങൾ നിർമ്മിക്കാൻ കഴിയും. വിശദമായ ലോഗോകൾ, പാറ്റേണുകൾ, ടെക്സ്റ്റ് എന്നിവ സൃഷ്ടിക്കുന്നതിന് ഇത് അനുയോജ്യമാക്കുന്നു.

- നോൺ-കോൺടാക്റ്റ് പ്രോസസ്സ്: ലേസർ ഗ്ലാസിൽ ശാരീരികമായി സ്പർശിക്കാത്തതിനാൽ, ഉപരിതലത്തിന് കേടുപാടുകൾ വരുത്താനോ പോറൽ ഏൽക്കാനോ സാധ്യതയില്ല. ഇത് ഗ്ലാസിൻ്റെ സമഗ്രതയും സുഗമവും നിലനിർത്തുന്നത് ഉറപ്പാക്കുന്നു.

- സ്ഥിരമായ അടയാളപ്പെടുത്തലുകൾ: ലേസർ സൃഷ്ടിച്ച കൊത്തുപണികൾ ശാശ്വതവും മങ്ങിപ്പോകുന്നതിനോ തേയ്മാനം സംഭവിക്കുന്നതിനോ പ്രതിരോധമുള്ളവയുമാണ്. ഈ ദൈർഘ്യം ലേസർ കൊത്തുപണികൾ അലങ്കാരവും പ്രായോഗികവുമായ ഉപയോഗങ്ങൾക്ക് അനുയോജ്യമാക്കുന്നു.

- ബഹുമുഖത: കുടിവെള്ള ഗ്ലാസുകൾ, മഗ്ഗുകൾ, പാത്രങ്ങൾ, ജാറുകൾ എന്നിവയുൾപ്പെടെയുള്ള ഗ്ലാസ് ഉൽപ്പന്നങ്ങളുടെ വിശാലമായ ശ്രേണിയിൽ ലേസർ കൊത്തുപണി പ്രയോഗിക്കാവുന്നതാണ്. ഈ ബഹുമുഖത വിപുലമായ ഇഷ്ടാനുസൃതമാക്കൽ ഓപ്ഷനുകൾ അനുവദിക്കുന്നു.

- കാര്യക്ഷമതയും ശുചിത്വവും: ഈ പ്രക്രിയ ശുദ്ധവും കാര്യക്ഷമവുമാണ്, കൂടാതെ കുറഞ്ഞ മാലിന്യങ്ങൾ ഉൽപ്പാദിപ്പിക്കുകയും ചെയ്യുന്നു, ഇത് വലിയ തോതിലുള്ള ഉൽപ്പാദനത്തിനുള്ള പരിസ്ഥിതി സൗഹൃദ ഓപ്ഷനാക്കി മാറ്റുന്നു.

ലേസർ കൊത്തുപണിയുടെ പ്രയോഗങ്ങൾ

- കോർപ്പറേറ്റ് ബ്രാൻഡിംഗ്: പ്രമോഷണൽ ഇനങ്ങൾ, കോർപ്പറേറ്റ് സമ്മാനങ്ങൾ അല്ലെങ്കിൽ ബ്രാൻഡഡ് ചരക്കുകൾ എന്നിവയ്ക്കായി ഗ്ലാസ്വെയറുകളിലേക്ക് ലോഗോകളും ബ്രാൻഡ് നാമങ്ങളും ചേർക്കുന്നു.

- വ്യക്തിഗതമാക്കിയ സമ്മാനങ്ങൾ: വിവാഹങ്ങൾ, വാർഷികങ്ങൾ അല്ലെങ്കിൽ ജന്മദിനങ്ങൾ പോലുള്ള പ്രത്യേക അവസരങ്ങൾക്കായി ഇഷ്ടാനുസൃത കൊത്തുപണികൾ.

- ഇവൻ്റ് മെമ്മോറബിലിയ: ഇവൻ്റ് പേരുകൾ, തീയതികൾ, അതുല്യമായ ഡിസൈനുകൾ എന്നിവ ഉപയോഗിച്ച് കീപ്സേക്കുകൾ സൃഷ്ടിക്കുന്നു.

- വീടിൻ്റെ അലങ്കാരം: കൊത്തുപണികളുള്ള ഗ്ലാസ്വെയർ മനോഹരവും വ്യക്തിഗതമാക്കിയതുമായ അലങ്കാര വസ്തുക്കളായി ഉപയോഗിക്കുന്നു.

വിസ്കി ഗ്ലാസുകൾക്കുള്ള ലേസർ ലോഗോ

ലേസർ കൊത്തുപണി സമയത്ത് ഗ്ലാസ് പൊട്ടൽ എങ്ങനെ കുറയ്ക്കാം

ലേസർ കൊത്തുപണി ഗ്ലാസ് ഒരു അതിലോലമായ പ്രക്രിയയാണ്, ശരിയായ മുൻകരുതലുകൾ ഇല്ലെങ്കിൽ, ഗ്ലാസ് തകരാനുള്ള സാധ്യതയുണ്ട്. പൊട്ടാനുള്ള സാധ്യത കുറയ്ക്കുന്നതിനും ഉയർന്ന നിലവാരമുള്ള കൊത്തുപണികൾ ഉറപ്പാക്കുന്നതിനുമുള്ള ചില തന്ത്രങ്ങൾ ഇതാ:

ഉചിതമായ ലേസർ ക്രമീകരണങ്ങൾ ഉപയോഗിക്കുക

ശക്തിയും വേഗതയും ക്രമീകരണം:

- താഴ്ന്ന പവർ: കുറഞ്ഞ ലേസർ പവർ ക്രമീകരണം ഉപയോഗിക്കുന്നത് ഗ്ലാസ് വളരെ വേഗത്തിൽ ചൂടാകുന്നത് തടയാൻ കഴിയും, ഇത് താപ സമ്മർദ്ദവും വിള്ളലും ഉണ്ടാകാനുള്ള സാധ്യത കുറയ്ക്കുന്നു.

- ഉയർന്ന വേഗത: ഉയർന്ന വേഗതയിൽ കൊത്തുപണി ചെയ്യുന്നത് ഏതെങ്കിലും ഒരു സ്ഥലത്തേക്കുള്ള ലേസർ എക്സ്പോഷറിൻ്റെ ദൈർഘ്യം കുറയ്ക്കുന്നു, ഇത് താപ ബിൽഡ്-അപ്പ് കൂടുതൽ കുറയ്ക്കുന്നു.

പൾസ് ഫ്രീക്വൻസി:

- ഉയർന്ന ഫ്രീക്വൻസി: ഉയർന്ന പൾസ് ഫ്രീക്വൻസി സജ്ജീകരിക്കുന്നത് ഗ്ലാസ് പ്രതലത്തിൽ കൂടുതൽ തുല്യമായി ലേസർ ഊർജ്ജം വിതരണം ചെയ്യും, പ്രാദേശിക ചൂടാക്കലും പൊട്ടാൻ സാധ്യതയുള്ള തകർച്ചയും തടയുന്നു.

ശരിയായ കൂളിംഗ് ടെക്നിക്കുകൾ

എയർ അസിസ്റ്റ്:

- വായു വീശുന്നു: ഒരു എയർ അസിസ്റ്റ് സിസ്റ്റം ഉപയോഗിച്ച്, കൊത്തുപണി പ്രദേശത്തിന് മുകളിലൂടെ വായുവിൻ്റെ ഒരു സ്ഥിരമായ പ്രവാഹം വീശാൻ കഴിയും, ഇത് ചൂട് ചിതറിക്കാനും ഗ്ലാസ് പ്രതലത്തെ തണുപ്പിക്കാനും സഹായിക്കുന്നു.

വാട്ടർ കൂളിംഗ്:

- വാട്ടർ സ്പ്രേ: കൊത്തുപണി സമയത്ത് ഗ്ലാസ് പ്രതലത്തിൽ നല്ല മൂടൽമഞ്ഞ് വെള്ളം പുരട്ടുന്നത് താപനില നിയന്ത്രിക്കാനും അമിതമായി ചൂടാകുന്നത് തടയാനും സഹായിക്കും.

- മുങ്ങൽ: ചില സന്ദർഭങ്ങളിൽ, കൊത്തുപണി സമയത്ത് ഗ്ലാസ് ഭാഗികമായി വെള്ളത്തിൽ മുക്കിവയ്ക്കുന്നത് ഫലപ്രദമായ തണുപ്പ് നൽകാം, എന്നിരുന്നാലും ലേസർ ഉപകരണത്തിന് വെള്ളം കേടുപാടുകൾ സംഭവിക്കാതിരിക്കാൻ ഇത് ശ്രദ്ധാപൂർവം സജ്ജീകരിക്കേണ്ടതുണ്ട്.

ഗ്ലാസിൻ്റെ പ്രീ-ട്രീറ്റ്മെൻ്റ്

അനീലിംഗ്:

- താപ ചികിത്സ: ഗ്ലാസ് സാവധാനം ചൂടാക്കി ക്രമേണ തണുപ്പിക്കുന്നതിലൂടെ ഗ്ലാസ് പ്രീ-അനിയൽ ചെയ്യുന്നത് ആന്തരിക സമ്മർദ്ദം കുറയ്ക്കുകയും കൊത്തുപണി സമയത്ത് താപ ഷോക്കിനെ കൂടുതൽ പ്രതിരോധിക്കുകയും ചെയ്യും.

ഉപരിതല കോട്ടിംഗ്:

- മാസ്കിംഗ്: ഗ്ലാസ് പ്രതലത്തിൽ ഡിഷ് സോപ്പിൻ്റെ നേർത്ത പാളിയോ പ്രത്യേക ലേസർ കൊത്തുപണികളോ പുരട്ടുന്നത് ചൂട് കൂടുതൽ തുല്യമായി പുറന്തള്ളാൻ സഹായിക്കും.

ഡിസൈനും ലേഔട്ടും ഒപ്റ്റിമൈസ് ചെയ്യുക

വലിയ സോളിഡ് ഏരിയകൾ ഒഴിവാക്കുക:

- പാറ്റേൺ ഡിസൈൻ: വലിയ ഖര പ്രദേശങ്ങൾ കൊത്തുപണി ചെയ്യുന്നത് ഗണ്യമായ ചൂട് വർദ്ധിപ്പിക്കുന്നതിന് കാരണമാകും. പകരം, താപ സമ്മർദ്ദം കുറയ്ക്കുന്നതിന് കൂടുതൽ ലൈനുകളും കുറഞ്ഞ സോളിഡ് ഫില്ലും ഉള്ള പാറ്റേണുകളും ഡിസൈനുകളും ഉപയോഗിക്കുക.

സ്പെയ്സിംഗ്:

- ഡിസൈൻ പ്ലേസ്മെൻ്റ്: മെച്ചപ്പെട്ട താപ വിതരണവും തണുപ്പും അനുവദിക്കുന്നതിന്, കൊത്തുപണികൾക്കിടയിൽ മതിയായ അകലം ഉണ്ടെന്ന് ഉറപ്പാക്കുക.

ഉപകരണങ്ങളുടെ പരിപാലനവും കാലിബ്രേഷനും

ലേസർ ഫോക്കസ്:

- ശരിയായ ഫോക്കസിംഗ്: അമിതമായ ചൂട് കൂടാതെ കൃത്യമായ കൊത്തുപണികൾ നേടുന്നതിന് ലേസർ ബീം ശരിയായി ഫോക്കസ് ചെയ്യുന്നത് നിർണായകമാണ്. പതിവായി ലേസർ ഫോക്കസ് പരിശോധിച്ച് ക്രമീകരിക്കുക.

ലെൻസും മിറർ ക്ലീനിംഗും:

- ക്ലീൻ ഒപ്റ്റിക്സ്: ഒപ്റ്റിമൽ പ്രകടനവും സ്ഥിരമായ കൊത്തുപണി ഗുണനിലവാരവും നിലനിർത്തുന്നതിന് ലേസറിൻ്റെ ലെൻസുകളും മിററുകളും വൃത്തിയുള്ളതും അവശിഷ്ടങ്ങൾ ഇല്ലാത്തതുമാണെന്ന് ഉറപ്പാക്കുക.

മെറ്റീരിയൽ കൈകാര്യം ചെയ്യലും തയ്യാറാക്കലും

ഗ്ലാസ് ഗുണനിലവാരം:

- ഉയർന്ന നിലവാരമുള്ള ഗ്ലാസ് ഉപയോഗിക്കുക: കുറഞ്ഞ മാലിന്യങ്ങളും ഉൾപ്പെടുത്തലുകളും ഉള്ള ഉയർന്ന നിലവാരമുള്ള ഗ്ലാസ് കൊത്തുപണി സമയത്ത് പൊട്ടിപ്പോകാനുള്ള സാധ്യത കുറവാണ്.

ഗ്ലാസ് കനം:

- ഉചിതമായ കനം: കൊത്തുപണി പ്രക്രിയയ്ക്ക് അനുയോജ്യമായ കട്ടിയുള്ള ഗ്ലാസ് ഉപയോഗിക്കുക. കനം കുറഞ്ഞ ഗ്ലാസ് പൊട്ടാനുള്ള സാധ്യത കൂടുതലാണ്, അതേസമയം കട്ടിയുള്ള ഗ്ലാസിന് താപ സമ്മർദ്ദത്തെ നന്നായി നേരിടാൻ കഴിയും.

ലേസർ കൊത്തുപണിക്ക് ശേഷം ഗ്ലാസ്വെയർ എങ്ങനെ വൃത്തിയാക്കാം

ലേസർ കൊത്തുപണിക്ക് ശേഷം നിങ്ങളുടെ ഗ്ലാസ്വെയർ മിനുക്കിയതും പ്രൊഫഷണലുമാണെന്ന് ഉറപ്പാക്കാൻ, ഈ ലളിതമായ ഘട്ടങ്ങൾ പാലിക്കുക:

- നനഞ്ഞ തുണി: ഏതെങ്കിലും അവശിഷ്ടങ്ങൾ നീക്കം ചെയ്യാൻ ചെറുചൂടുള്ള വെള്ളത്തിൽ നനച്ച തുണി ഉപയോഗിച്ച് കൊത്തുപണി ചെയ്ത ഗ്ലാസ് സൌമ്യമായി തുടയ്ക്കുക.

- ഉണങ്ങിയ തുണി: വ്യക്തവും തിളക്കവുമുള്ള ഫിനിഷിംഗ് ഉറപ്പാക്കാൻ വൃത്തിയുള്ളതും ഉണങ്ങിയതുമായ തുണി ഉപയോഗിച്ച് ഗ്ലാസ് തുടയ്ക്കുക.

ഒരു നല്ല ഗ്ലാസ്വെയർ ലേസർ കൊത്തുപണി സേവനം എങ്ങനെ തിരഞ്ഞെടുക്കാം എന്നതിനെക്കുറിച്ചുള്ള നുറുങ്ങുകൾ

മികച്ച ഫലങ്ങൾ ലഭിക്കുന്നതിന് നിങ്ങളുടെ ഗ്ലാസ്വെയറിനായി ശരിയായ ലേസർ കൊത്തുപണി സേവനം തിരഞ്ഞെടുക്കുന്നത് പ്രധാനമാണ്. ഒരു നല്ല സേവനം തിരഞ്ഞെടുക്കാൻ നിങ്ങളെ സഹായിക്കുന്ന ചില നുറുങ്ങുകൾ ഇതാ:

അനുഭവവും നൈപുണ്യവും പരിശോധിക്കുക

- അനുഭവം: ലേസർ കൊത്തുപണി ഗ്ലാസിൽ ധാരാളം അനുഭവപരിചയമുള്ള ഒരു കമ്പനിയെ തിരയുക. പരിചയസമ്പന്നരായ കമ്പനികൾ സാധാരണയായി മികച്ച ജോലി ചെയ്യുന്നു.

- വിദഗ്ധ തൊഴിലാളികൾ: ലേസർ കൊത്തുപണി യന്ത്രങ്ങൾ എങ്ങനെ ശരിയായി ഉപയോഗിക്കണമെന്ന് അറിയാവുന്ന വിദഗ്ധരായ സാങ്കേതിക വിദഗ്ധർ അവർക്കുണ്ടെന്ന് ഉറപ്പാക്കുക.

അവരുടെ മുമ്പത്തെ ജോലി നോക്കുക

- പോർട്ട്ഫോളിയോ: അവരുടെ മുൻ ജോലിയുടെ സാമ്പിളുകൾ കാണാൻ ആവശ്യപ്പെടുക. ഇത് അവരുടെ കൊത്തുപണികളുടെ ഗുണനിലവാരം കാണിക്കും.

- അവലോകനങ്ങൾ: മറ്റുള്ളവർ അവരുടെ സേവനങ്ങളിൽ സന്തുഷ്ടരാണോ എന്ന് കാണാൻ ഉപഭോക്തൃ അവലോകനങ്ങൾ വായിക്കുക.

അവരുടെ ഉപകരണങ്ങൾ പരിശോധിക്കുക

- ആധുനിക യന്ത്രങ്ങൾ: ഏറ്റവും പുതിയ ലേസർ കൊത്തുപണി യന്ത്രങ്ങൾ ഉപയോഗിക്കുന്ന ഒരു കമ്പനി തിരഞ്ഞെടുക്കുക. ആധുനിക ഉപകരണങ്ങൾ സാധാരണയായി മികച്ച നിലവാരം എന്നാണ് അർത്ഥമാക്കുന്നത്.

- നന്നായി പരിപാലിക്കുന്നു: നല്ല പ്രകടനം ഉറപ്പാക്കാൻ അവർ പതിവായി അവരുടെ മെഷീനുകൾ പരിപാലിക്കുകയും കാലിബ്രേറ്റ് ചെയ്യുകയും ചെയ്യുന്നുണ്ടോ എന്ന് ചോദിക്കുക.

ഇഷ്ടാനുസൃതമാക്കൽ ഓപ്ഷനുകൾ

- ഡിസൈൻ ഫ്ലെക്സിബിലിറ്റി: വ്യത്യസ്ത ഡിസൈനുകളും ലോഗോകളും വ്യക്തിഗതമാക്കിയ ടെക്സ്റ്റും അവർക്ക് കൈകാര്യം ചെയ്യാനാകുമെന്ന് ഉറപ്പാക്കുക.

- ഡിസൈൻ സഹായം: ഒരു നല്ല കമ്പനി നിങ്ങളുടെ ഡിസൈൻ ആശയങ്ങൾ കൊത്തുപണി ചെയ്യുമ്പോൾ അവ മനോഹരമായി കാണപ്പെടുന്നുവെന്ന് ഉറപ്പാക്കാൻ സഹായം നൽകും.

ഗുണനിലവാര നിയന്ത്രണം

- ഉയർന്ന നിലവാരം: ഓരോ ഭാഗവും മികച്ചതാണെന്ന് ഉറപ്പാക്കാൻ കർശനമായ ഗുണനിലവാര പരിശോധനകളുള്ള ഒരു സേവനം തിരഞ്ഞെടുക്കുക.

- സ്ഥിരത: പ്രത്യേകിച്ച് വലിയ ഓർഡറുകൾക്ക് അവർക്ക് സ്ഥിരമായ ഗുണനിലവാരം ഉൽപ്പാദിപ്പിക്കാൻ കഴിയുമെന്ന് ഉറപ്പാക്കുക.

തിരിയുന്ന സമയം

- കൃത്യസമയത്ത് ഡെലിവറി: അവർക്ക് നിങ്ങളുടെ ഓർഡർ എത്ര വേഗത്തിൽ പൂർത്തിയാക്കാനാകുമെന്ന് പരിശോധിക്കുക. തിരക്കിട്ട് ഗുണനിലവാരം കുറയ്ക്കാതെ അവർ നിങ്ങളുടെ സമയപരിധി പാലിക്കണം.

- ഓർഡർ അപ്ഡേറ്റുകൾ: നിങ്ങളുടെ ഓർഡറിൻ്റെ പുരോഗതിയെക്കുറിച്ചുള്ള അപ്ഡേറ്റുകൾ നൽകുന്ന ഒരു സേവനത്തിനായി തിരയുക.

വിലനിർണ്ണയം

- ന്യായമായ വിലകൾ: നിങ്ങൾക്ക് ന്യായമായ ഡീൽ ലഭിക്കുന്നുണ്ടെന്ന് ഉറപ്പാക്കാൻ വ്യത്യസ്ത സേവനങ്ങളിൽ നിന്നുള്ള വിലകൾ താരതമ്യം ചെയ്യുക.

- മൂല്യം: വില മാത്രമല്ല, ഗുണനിലവാരവും ഉപഭോക്തൃ സേവനവും ഉൾപ്പെടെ മൊത്തത്തിലുള്ള മൂല്യം പരിഗണിക്കുക.

കസ്റ്റമർ സർവീസ്

- പ്രതികരണശേഷിയുള്ള: ബന്ധപ്പെടാൻ എളുപ്പമുള്ളതും നിങ്ങളുടെ ചോദ്യങ്ങളോട് പെട്ടെന്ന് പ്രതികരിക്കുന്നതുമായ ഒരു കമ്പനി തിരഞ്ഞെടുക്കുക.

- വിൽപ്പനാനന്തര പിന്തുണ: നിങ്ങൾക്ക് എന്തെങ്കിലും പ്രശ്നങ്ങളുണ്ടെങ്കിൽ വിൽപ്പനയ്ക്ക് ശേഷം അവർ നല്ല പിന്തുണ വാഗ്ദാനം ചെയ്യുന്നുണ്ടെന്ന് ഉറപ്പാക്കുക.

എന്തുകൊണ്ടാണ് ഡിഎം ഗ്ലാസ്വെയർ തിരഞ്ഞെടുക്കുന്നത്?

ഡിഎം ഗ്ലാസ്വെയറിൽ, ഞങ്ങൾ മികച്ചത് നൽകുന്നു ഗ്ലാസ്വെയർ ലേസർ കൊത്തുപണി സേവനങ്ങൾ. എന്തുകൊണ്ടാണ് നിങ്ങൾ ഞങ്ങളെ തിരഞ്ഞെടുക്കേണ്ടതെന്ന് ഇതാ:

- പരിചയസമ്പന്നരായ ടീം: ഞങ്ങളുടെ വൈദഗ്ധ്യമുള്ള സാങ്കേതിക വിദഗ്ധരും വർഷങ്ങളുടെ അനുഭവസമ്പത്തും മികച്ച നിലവാരമുള്ള കൊത്തുപണികൾ ഉറപ്പാക്കുന്നു.

- നൂതന യന്ത്രങ്ങൾ: കൃത്യവും വിശദവുമായ കൊത്തുപണികൾക്കായി ഞങ്ങൾ ഏറ്റവും പുതിയ സാങ്കേതികവിദ്യ ഉപയോഗിക്കുന്നു.

- ഇഷ്ടാനുസൃതമാക്കൽ: നിങ്ങളുടെ ആവശ്യങ്ങൾക്ക് അനുയോജ്യമായ ഡിസൈൻ ഓപ്ഷനുകൾ ഞങ്ങൾ വാഗ്ദാനം ചെയ്യുന്നു.

- ഗുണനിലവാര നിയന്ത്രണം: ഓരോ ഭാഗവും ഞങ്ങളുടെ ഉയർന്ന നിലവാരം പുലർത്തുന്നുവെന്ന് ഉറപ്പാക്കാൻ പരിശോധിക്കുന്നു.

- മത്സര വിലകൾ: ന്യായമായ വിലകളും ഉയർന്ന നിലവാരമുള്ള സേവനവും ഉപയോഗിച്ച് ഞങ്ങൾ പണത്തിന് വലിയ മൂല്യം വാഗ്ദാനം ചെയ്യുന്നു.

- മികച്ച ഉപഭോക്തൃ സേവനം: പ്രക്രിയയിലുടനീളം നിങ്ങളെ സഹായിക്കാൻ ഞങ്ങളുടെ ടീം ഇവിടെയുണ്ട്.

ഞങ്ങളെ സമീപിക്കുക ഇന്ന് ഞങ്ങളുടെ സേവനങ്ങളെക്കുറിച്ചും നിങ്ങളുടെ ഇഷ്ടാനുസൃത ഗ്ലാസ്വെയർ ആവശ്യങ്ങൾക്ക് എങ്ങനെ സഹായിക്കാമെന്നും കൂടുതലറിയാൻ.

ലേസർ കൊത്തിയ ലോഗോകളുള്ള ഞങ്ങളുടെ ഗ്ലാസ് കപ്പുകൾ ചുവടെ പരിശോധിക്കുക.

ഉപസംഹാരം

നിങ്ങളുടെ ഗ്ലാസ്വെയർ വ്യക്തിഗതമാക്കുന്നതിനും ഉയർത്തുന്നതിനുമുള്ള മികച്ച മാർഗമാണ് ലേസർ കൊത്തുപണി.

ചെയ്തത് ഡിഎം ഗ്ലാസ്വെയർ, നിങ്ങളുടെ ബ്രാൻഡ് ഐഡൻ്റിറ്റി പ്രതിഫലിപ്പിക്കുന്ന അതുല്യവും ഫലപ്രദവുമായ ഉൽപ്പന്നങ്ങൾ സൃഷ്ടിക്കാൻ നിങ്ങളെ സഹായിക്കുന്ന ഈ സേവനം നിങ്ങൾക്ക് വാഗ്ദാനം ചെയ്യുന്നതിൽ ഞങ്ങൾ അഭിമാനിക്കുന്നു.

കൂടുതലറിയാനും നിങ്ങളുടെ ഇഷ്ടാനുസൃത ഗ്ലാസ്വെയർ പ്രോജക്റ്റ് ആരംഭിക്കാനും ഇന്ന് ഞങ്ങളെ ബന്ധപ്പെടുക.

ഡിഎം ഗ്ലാസ്വെയർ വിവിധ അവസരങ്ങൾക്കായി കസ്റ്റം ഗ്ലാസ്വെയർ നൽകുന്നു.

ഞങ്ങളുടെ പ്രധാന ഉൽപ്പന്നങ്ങൾ മെഷീൻ നിർമ്മിതമാണ് ഗ്ലാസ്വെയർ, ഗ്ലാസ് കപ്പുകൾ, ഗ്ലാസ് പാനീയങ്ങൾ വീട്ടിലും അടുക്കളയിലും ഉപയോഗിക്കാനുള്ള ടേബിൾവെയറുകളും. അത്തരം ഗ്ലാസുകൾ ഇഷ്ടപ്പെടുന്നു ഗ്ലാസ് ടംബ്ലറുകൾ, ഗ്ലാസ് മഗ്ഗുകൾ, വിസ്കി ഗ്ലാസുകൾ, ഷോട്ട് ഗ്ലാസുകൾ, ഗ്ലാസ് മിഠായി പാത്രങ്ങൾ, ഗ്ലാസ് പാത്രങ്ങൾ, ബിയർ ഗ്ലാസുകൾ, തുടങ്ങിയവ.

വ്യത്യസ്ത ഡിസ്പ്ലേ ബോക്സുകൾ, സ്റ്റിക്കറുകൾ ചേർക്കൽ, ടാഗുകൾ മുതലായവ പോലുള്ള വ്യത്യസ്ത വിൽപ്പന തരങ്ങളെ അടിസ്ഥാനമാക്കി ഏറ്റവും അനുയോജ്യമായ പാക്കേജിംഗ് രീതിയും ഞങ്ങൾ ശുപാർശ ചെയ്യുന്നു.

സമീപകാല പോസ്റ്റുകൾ

സ്റ്റെംലെസ് വൈൻ ഗ്ലാസുകൾ വീഞ്ഞിന് നല്ലതാണോ?

റെഡ് വൈനിന് ഏറ്റവും അനുയോജ്യമായ വൈൻ ഗ്ലാസ് ഏതാണ്?

വ്യത്യസ്ത തരം വൈൻ ഗ്ലാസുകൾ എന്തൊക്കെയാണ്?