Whiskey Glasses Manufacturing Factory

DM Glassware is manufacturing a wide range of whiskey glasses for years. From design, prototyping, custom, production, surface decoration, we are an expert in this area.

Custom Whiskey Glasses

Whiskey Glasses are used to have drinks of whiskey, bourbon, and scotch. They are also a type of whiskey tumbler glass. They are highly welcomed by people all over the world.

Our product catalogue includes quite a lot of hot models. From round shape, square shape to with/without pattern. The best whiskey glasses are with crystal patterns. They also can be called old fashioned whiskey glasses or vintage whiskey glasses.

DM glassware design and produce personalized whiskey glasses for many years. We can custom the patterns for best enjoying. To state your own branding effect, we can make your logo by laser on the bottom. Also, an unique packing boxes are the must for these unique whiskey glasses.

DM is one whiskey glasses supplier in China. If you have any projects in this area, you will find all solutions at DM.

Choose From Our Whiskey Glasses Catalogue

DM331 Series

Features of Our Whiskey Tumbler Glasses

White & Clear

Our raw material is high-white soda lime glass. With special formulation, our glasses are pure white and transparent. They are just like diamonds.

Product Variety

We provide a wide variety of whiskey glasses to cater to different customer preferences, ensuring you have everything you need under one roof.

Quality Control

Our QC team are keeping supervising the whole production, making sure every piece of whiskey glass are good.

Design and Custom

Our innovative designs and customization options, including logo decals, engraving, and painting, help you create unique products that reflect your brand.

Application Scenarios for Whiskey Glasses

Bars and Restaurants

Enhance the presentation of premium whiskey, bourbon, and scotch, offering customers a refined drinking experience.

Home Use

Perfect for personal enjoyment or entertaining guests, our whiskey glasses add a touch of sophistication to any home bar setup.

Corporate Gifts

Customizable whiskey tumblers make excellent corporate gifts, promoting your brand with engraved logos or personalized designs.

What materials are used to make whiskey glasses?

High-white Soda Lime Glass

Soda-calcium glass, also known as soda-lime silicate glass, is composed of the following raw materials:

Silicon dioxide (SiO2): from quartz sand, one of the main components of glass, giving it hardness and chemical stability.

Calcium oxide (CaO): from limestone (CaCO3) or calcite (CaO), which helps to adjust the melting point and chemical properties of the glass.

Sodium oxide (Na2O): from soda ash (Na2CO3), which lowers the melting point of the glass and increases its plasticity.

These ingredients are mixed together after precise weighing and undergo a high-temperature melting process to form a homogeneous glass liquid.

During the molding process, the molten glass liquid is blown into the mold, and various shapes of glass products are obtained by controlling the amount of blowing and the shape of the mold. After molding, the glass products need to be annealed to remove internal stresses and improve strength and stability.

This is our raw material workshop.

What is the manufacturing process for whiskey glasses?

As the main production process for glass molding, press molding has become one of the most effective molding processes for glass products due to its fast, efficient and precise characteristics.

In compression molding, raw materials such as sand, lime and soda are first heated and melted in a furnace at degrees Celsius to produce liquid glass. After homogenization and purification, the molten glass is stored in a discharge cylinder.

This is the production process of fire polishing to make the glass product smooth and flat.

Manufacturing Techniques

During forming, the molten glass is extruded and truncated to form a mass of glass droplets.

The glass droplets are then fed into a low-temperature mold, which is filled with compressed air or plunger pressure, cooled and allowed to fully cure before being removed from the mold and sucked out.

After the glass cup is taken out, the mouth is relatively flat, but there may be burrs if it is not handled well, which requires a baking mouth, which is placed on the baking machine and burns the mouth of the glass cup with a fire (the cup is placed on the baking machine and is rotating), so that the glass burrs are melted twice, thus making the mouth of the glass cup very flat.

Then, the glass product into the glass annealing furnace annealing, eliminating the internal stress of the glass (not after annealing the glass is easy to burst), and finally, from the annealing furnace out of the glass is the usual glass finished cup.

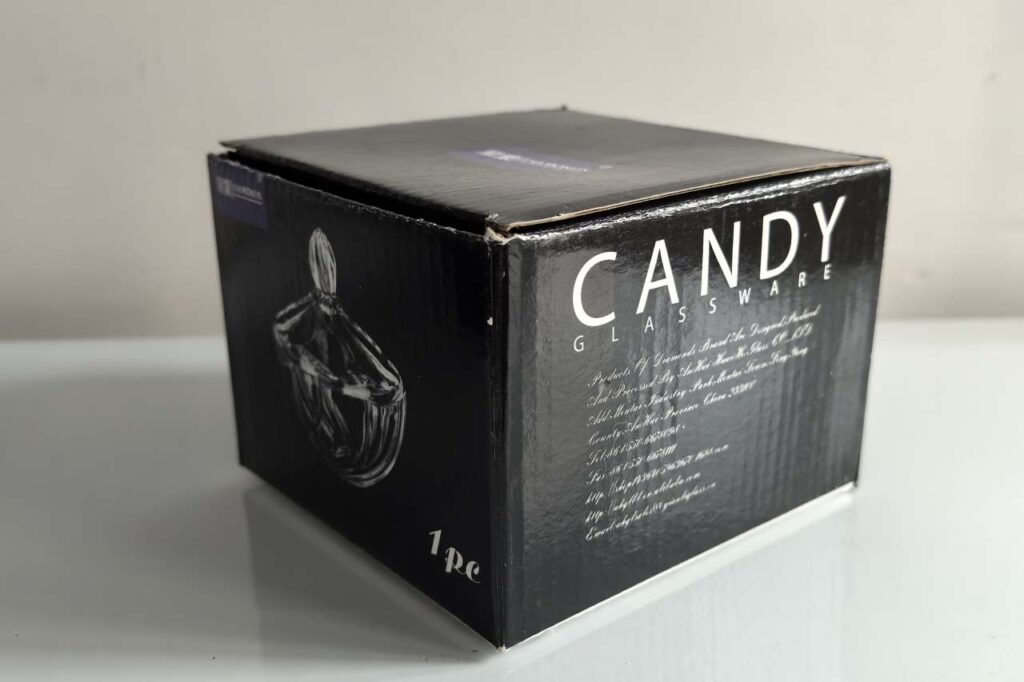

Packaging Options for Whiskey Glasses

Individual Box Packaging

- Description: Each whiskey glass is packed in its own sturdy box for maximum protection.

- Best for: High-end, luxury whiskey glasses or gifts.

- Advantages: Adds a premium feel and ensures the glass remains safe during shipping or storage.

Set Packaging

- Description: Multiple whiskey glasses are packed together in a single box, typically in sets of 2, 4, or 6.

- Best for: Retailers or customers purchasing sets for home use or gifts.

- Advantages: Economical and efficient, perfect for gift sets or bulk orders.

Branded Packaging

- Description: Packaging customized with your logo, brand colors, or designs.

- Best for: Businesses aiming to enhance brand visibility through packaging.

- Advantages: Offers a personalized touch and makes the unboxing experience more memorable for customers.

Custom Options

Logo decal is very common glass finishing process to make your brand stand out. It is inexpensive and displays a variety of colors.

The breakage rate is also very low during the operation. Decals can be chosen from environmentally friendly types that meet food safety certifications.

This is the laser or sandblasting process, a process that displays the product logo by destroying the surface of the glass.

This kind of logo is touchable by hand and very textured. For whiskey glasses with patterned surface, we can engrave on the bottom of the glass.

Customizing the size and finish of a whiskey glass requires a certain starting order. With custom molds, you can produce exclusive product shapes and patterns, as well as brand logos.

The cost of customizing the product would just be the added cost of the mold, but it’s well worth it for the branding.

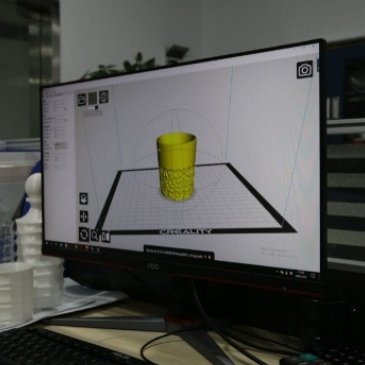

Process Of Production

3D Modeling

3D Photocopying

Engraving by Hand

Logo Lasering

Frequently Asked Questions on Whiskey Glasses

The lead time for production varies depending on different occasions. If you want to buy from our stocks, we can make the delivery in 3 days. For custom orders, it usually takes 40-45 days for production after order confirmation.

For our stocks, 1 carton starts with our packagings.

For custom glasses, there are two different situations:

1- You need our clear glass cups with your own logos or decorations, MOQ is 10000pcs. You can have the outer carton with your own shipping marks.

2- To produce your custom designs and make new mouldings, the MOQ will be 80k – 100k pcs.

For clear glass cup sample, it’s free of charge. You only need to pay express cost or provide your courier account.

If you want to make a logo sample or decorated one, the sampling cost is USD50-USD100.

For customizing new glasses with different shape, please check with our team.

Yes, for sure. You can come to visit anytime.

We offer various types of whiskey glasses including rocks glasses and highball glasses.

Yes, we provide customization options such as logo decals, engraving, and painting to personalize your whiskey glasses.

Yes, we offer competitive pricing and discounts for bulk orders. Please contact our sales team for a detailed quote.

Yes, our whiskey glasses are dishwasher safe. However, we recommend hand washing for customized and engraved glasses to preserve the design.

Related Posts

Custom Whiskey Glasses Manufacturing Services

10+ Years of Experience. Various Glassware Designs. Professional R&D Team. Competitive Price.