Borosilicate Glass vs Soda Lime Glass: What You Need to Know Before Buying

Glass is everywhere — from the everyday drinking cup to the cutting-edge laboratory equipment that drives scientific discovery. Yet, not all glass is created equal. Two of the most widely used types, borosilicate glass and soda lime glass, each have distinct properties that make them ideal for different purposes.

Whether you’re using glass in the kitchen, lab, or home, understanding the key differences between these two materials can help you choose the right one for your needs.

In this article, we’ll dive into a detailed comparison of borosilicate vs soda lime glass, uncovering which type reigns supreme for specific applications.

Table of Contents

What is Borosilicate Glass?

Borosilicate glass is a type of glass that is known for its remarkable strength and resistance to extreme temperatures.

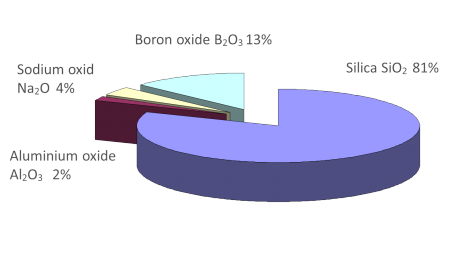

It is made primarily of silica and boron trioxide, giving it superior durability and heat tolerance compared to other types of glass. This composition allows borosilicate glass to withstand rapid temperature changes, making it an ideal material for applications where thermal shock resistance is essential.

Borosilicate Glass Properties

The key to borosilicate glass properties lies in its unique chemical composition. With about 80% silica and 13% boron oxide, it boasts a low coefficient of thermal expansion, meaning it can endure sudden temperature fluctuations without breaking. This makes it heat-resistant glass, perfect for laboratory settings and cookware alike.

Common uses of borosilicate glass include lab equipment, where its durability and resistance to chemical corrosion make it the top choice for beakers, test tubes, and flasks. The material’s reliability also extends to scientific instruments that require precision and safety under high temperatures, such as thermometers and condensers.

In the kitchen, borosilicate glass in cookware is highly valued for its ability to withstand high heat and extreme temperature changes without cracking.

Popular brands like Pyrex use borosilicate glass in their baking dishes, measuring cups, and storage containers, ensuring that users can rely on the glass for both cooking and food storage. Its non-reactive properties also make it an excellent choice for food and beverage applications, as it won’t leach chemicals into your food.

What is Soda Lime Glass?

Soda lime glass is the most commonly used type of glass in everyday life, known for its simplicity and cost-effectiveness.

It is made from a mixture of silica (sand), soda (sodium carbonate), and lime (calcium oxide), with small amounts of other materials such as alumina and magnesium oxide. This blend gives soda lime glass its characteristic clarity and transparency, but it is not as heat-resistant or durable as borosilicate glass.

Soda Lime Glass Properties

The properties of soda lime glass are largely defined by its composition. While it is a versatile material that offers decent strength and transparency, it has a higher thermal expansion compared to borosilicate glass, making it more prone to breaking under extreme temperature changes. Soda lime glass is also relatively more susceptible to chemical corrosion over time, especially when exposed to harsh chemicals or high heat.

Despite these limitations, soda lime glass is used in a wide variety of applications due to its cost-effectiveness and accessibility. It is the material of choice for many everyday products, including windows, bottles, and containers. Its affordability and ease of production make it ideal for mass-produced items such as drinkware, jars, and even decorative glassware.

In addition to its practical uses, soda lime glass remains popular for its aesthetic appeal in many consumer products. Its availability in a wide range of shapes, sizes, and finishes makes it a go-to material for both functional and decorative pieces. The relatively low cost of soda lime glass also makes it accessible for a wide variety of industries and consumers, ensuring its continued dominance in the global glass market.

Borosilicate Glass vs Soda Lime Glass: A Detailed Comparison

When it comes to choosing between borosilicate glass and soda lime glass, it’s crucial to understand the key differences in composition, heat resistance, chemical resistance, thermal shock resistance, and durability. Below is a comparison table to help you quickly grasp the distinct features of each type of glass.

| Property | Borosilicate Glass | Soda Lime Glass |

|---|---|---|

| Composition | Primarily silica (80%) and boron oxide (13%) | Silica, soda (sodium carbonate), and lime (calcium oxide) |

| Heat Resistance | Excellent; can withstand high temperatures and rapid changes | Not perfect; prone to cracking under high heat or temperature fluctuations |

| Chemical Resistance | Superior; resistant to acids, alkalis, and most chemicals | Limited; more susceptible to corrosion and chemical degradation |

| Thermal Shock Resistance | Very high; ideal for sudden temperature changes (e.g., from hot to cold) | Normal; breaks easily when exposed to extreme temperature changes |

| Durability | Very durable; resistant to mechanical stress and impact | Less durable; breaks more easily under stress or impact |

| Common Uses | Laboratory equipment, cookware, high-performance glassware | Everyday products like glass bottles, windows, jars, and food containers |

| Cost | Higher due to manufacturing complexity | More affordable and mass-produced |

Soda-Lime Glass

Borosilicate Glass

How To Choose Between The Two

For procurement department focused on daily use products, it’s essential to compare borosilicate glass and soda lime glass from multiple perspectives such as use cases, budget, product design, and durability. Below is a detailed comparison and guidance based on different customer needs.

1. Use Comparison

Borosilicate Glass for Daily Use Products

- Kitchenware: Ideal for heat-resistant bakeware, measuring cups, mixing bowls, and other kitchen tools, perfect for those who enjoy baking or need high-temperature cooking.

- Heat-resistant Drinkware: Products like coffee mugs, teapots, and glass jars that can handle hot and cold beverages without cracking.

- Storage Containers: Borosilicate glass storage boxes are great for storing food, as they are microwave-safe, and non-reactive with food.

Soda Lime Glass for Daily Use Products

Glassware: Ideal for drinking glasses, wine glasses, and tumblers. Soda lime glass is widely used in the production of everyday drinkware due to its clarity, ease of production, and affordability.

Storage Containers: Soda lime glass is also commonly used for storage jars, food containers, and spice jars. Its lightweight and transparent nature make it perfect for organizing and storing dry goods in kitchens.

Tableware: Used for plates, bowls, and serving dishes. Soda lime glass is versatile and perfect for creating functional tableware for everyday dining, offering both durability and an attractive aesthetic.

Vases and Decor: It’s a popular choice for creating simple yet elegant vases, decorative jars, and other home accessories. While the design is typically more straightforward, it suits modern and minimalist home decor.

2. Budget and Cost-Effectiveness Analysis

Borosilicate Glass Daily Use Products

Higher Cost: The cost of borosilicate glass is relatively high, not only due to the expensive materials used (such as boron oxide and silica) but also because the production process is semi-manual or fully manual. Skilled artisans often craft borosilicate glass items by hand or using specialized equipment, which adds to the labor and time involved in production. This craftsmanship contributes to its higher price point.

Target Market: Ideal for customers who prioritize high-quality, durable, and long-lasting products. Borosilicate glass is especially suited for those seeking premium kitchenware, laboratory equipment, or high-end applications that require heat resistance and precision.

Soda Lime Glass Daily Use Products

Lower Cost: Soda lime glass is much more affordable because it is primarily produced through fully automated processes. The raw materials (such as sand, soda, and lime) are melted at high temperatures and molded using machines, allowing for high-volume production at a lower cost. This makes soda lime glass suitable for mass production of everyday consumer products.

Target Market: Best for customers with a limited budget or those needing large quantities of products. Soda lime glass is widely used for restaurants, hotels, promotional items, and retail applications where high volumes of products are required at an affordable price.

3. Product Design

Borosilicate Glass Product Design

Tube Shaping and Cylindrical Forms: Most borosilicate glass products are made from pre-formed borosilicate tubes that are heated and shaped, resulting in cylindrical shapes like test tubes, flasks, and beakers commonly used in laboratories. These items often feature uniform, functional designs that prioritize precision.

Handcrafted and Unique Designs: For more artistic and decorative products, such as cocktail glasses in the shape of a swan, borosilicate glass can be crafted by hand, allowing for more complex and creative forms. This makes it suitable for high-end or custom items that demand intricate detailing.

Soda Lime Glass Product Design

Molded and Mass-Produced Shapes: Soda lime glass is typically created by melting granular materials at high temperatures and then shaping them in molds. This process is perfect for producing standard, everyday products like drinking glasses, wine glasses, glass bottles, and bowls.

Simple and Functional: The molding process allows for easy replication of common shapes and functional designs. It’s ideal for creating high volumes of affordable products that are durable and versatile in everyday settings.

4. Durability and Long-Term Use

Borosilicate Glass Daily Use Products

Borosilicate glass is known for its excellent durability. It is highly resistant to thermal shock, meaning it can handle rapid temperature changes without breaking. This makes it ideal for bakeware and laboratory glassware. It is also chemically resistant, which adds to its long-lasting reliability, even in harsh conditions. Products made from borosilicate glass are built to last and perform well over time.

Soda Lime Glass Daily Use Products

Soda lime glass is durable for everyday use but is less resistant to thermal shock than borosilicate glass. It can crack or break when exposed to sudden temperature changes. It is well-suited for items like drinking glasses, bottles, and basic kitchenware, offering sufficient durability for normal use but is less robust than borosilicate glass in extreme conditions.

Cases Telling You How To Choose

Case 1: Promotional Drinkware for a Liquor Brand

A gift company receives a request from a liquor brand to create a batch of customized glassware with the brand’s logo for a promotional campaign. The goal is to produce a large quantity of glassware that will be affordable and functional for distribution at events and as giveaways.

- Material Choice: Soda Lime Glass

- Reasoning: Given the budget constraints and the high volume needed for this promotional campaign, soda lime glass is the ideal choice. It is cost-effective and suitable for mass production using automated processes, allowing the company to produce the required quantity at a lower cost. While the quality and design are important, the focus is on functionality and cost-effectiveness for a large-scale promotional product.

Case 2: Custom Coffee Cups for a Boutique Café

A coffee shop wants to create a small batch of branded coffee cups for their customers to purchase as part of the café’s merchandise line. They plan to add the shop’s logo to the cups, and the total number of cups needed is relatively small.

- Material Choice: Borosilicate Glass

- Reasoning: Since the coffee shop is looking for a premium product that reflects the café’s unique brand identity, borosilicate glass is the better choice. The material’s high durability and heat resistance make it ideal for creating coffee mugs that are both practical and stylish. Additionally, the ability to customize with a logo is easy with borosilicate glass, and the smaller quantity makes it feasible despite the higher cost compared to soda lime glass.

Decorations on Both Materials

The post-processing techniques used for both borosilicate glass and soda lime glass are very similar, offering a wide range of options to enhance the appearance of the glassware for branding and promotional purposes. Here are some common decoration methods that work well for both materials:

Decal Printing

- Description: This method involves transferring vibrant, detailed designs or logos onto the surface of the glass using high-quality decals.

- Application: Ideal for adding complex logos, graphics, or artistic patterns. It is commonly used for promotional events, business branding, and product customization.

- Perfect For: Both borosilicate glass and soda lime glass products, including drinkware and customized glassware.

Logo Customization

- Description: Personalizing glassware with screen-printed logos, text, or slogans for a clean, professional finish.

- Application: This method provides sharp, high-quality branding, making it a popular choice for businesses, events, and giveaways.

- Perfect For: Both borosilicate glass and soda lime glass products, especially branded promotional glasses, coffee mugs, and event giveaways.

Electroplating

- Description: A reflective metallic coating is applied to the glass to achieve a modern and luxurious look, with options for different finishes like gold, silver, or chrome.

- Application: Great for premium branding or luxury designs. It gives glass products a high-end, sophisticated appearance.

- Perfect For: Typically used on borosilicate glass to enhance its premium appeal, but can also be applied to soda lime glass for high-end items like decorative drinkware or gift sets.

Acid Etching

- Description: Creates a frosted matte design on the glass surface, offering a subtle, elegant finish.

- Application: This technique is perfect for intricate logos, patterns, or sophisticated branding, offering a more refined look.

- Perfect For: Both types of glass, especially for high-end glassware, corporate gifts, or branded items that require a sleek, understated design.

Laser Engraving

Description: Laser engraving uses a focused laser beam to burn or vaporize the glass surface, leaving a permanent, high-contrast mark. The process creates sharp, precise lines and can be used to engrave logos, text, or intricate patterns directly onto the glass.

Application: Ideal for creating permanent branding, detailed logos, monograms, or personalized messages. It’s commonly used for corporate gifts, high-end drinkware, and specialty glass products.

Perfect For: Both borosilicate glass and soda lime glass, especially for items that require a high level of precision and durability. Laser engraving is especially effective for premium products like wine glasses, coffee mugs, gift items, or laboratory glassware.

Benefits: Laser engraving offers a clean, permanent finish that won’t wear off over time, making it ideal for high-end products or items that will be used frequently. It also provides a unique, sophisticated touch, adding an extra level of professionalism to any glassware.

See Also: How To Customize Glass Cups in Bulk?

Conclusion

The choice between borosilicate glass and soda lime glass depends on your budget and desired quality. Borosilicate glass offers premium durability and heat resistance, making it ideal for high-end products like custom drinkware. It’s perfect for businesses seeking sophisticated branding.

Soda lime glass is more cost-effective and suited for high-volume production, such as promotional items and branded giveaways. Both materials can be easily customized with techniques like laser engraving and decal printing, allowing you to effectively promote your brand.

FAQ

1. What is the main difference between borosilicate glass and soda lime glass?

Borosilicate glass is more durable, heat-resistant, and chemically resistant, making it ideal for high-end products, laboratory equipment, and cookware. Soda lime glass is more affordable and used for everyday items like drinkware, bottles, and containers.

2. Can both types of glass be customized with logos or designs?

Yes, both borosilicate glass and soda lime glass can be customized using techniques such as decal printing, laser engraving, acid etching, and screen printing for branding or promotional purposes.

3. Which glass is better for promotional items?

Soda lime glass is typically the better choice for promotional items because it is cost-effective and suitable for large-scale production, making it ideal for giveaways, branded glassware, and corporate events.

4. Is borosilicate glass more expensive than soda lime glass?

Yes, borosilicate glass is more expensive due to its higher material cost and the semi-manual or manual production process. It’s used for premium products that require durability and heat resistance.

5. Can borosilicate glass break easily?

While borosilicate glass is highly resistant to thermal shock and chemicals, it can still break if subjected to strong physical impacts. However, it’s generally more durable than soda lime glass in everyday use.

6. What are the best applications for soda lime glass?

Soda lime glass is best for everyday products like drinking glasses, bottles, and containers. It’s also commonly used for mass-produced items due to its affordable price and versatility.

7. Can both types of glass be used in the dishwasher?

Yes, both borosilicate and soda lime glass are dishwasher-safe, but it’s always best to check specific care instructions for each product to ensure longevity.

DM Glassware is providing custom glasswares for various occasions.

Our main products are machine-made glasswares, glass cups, glass drinkwares and tablewares for home and kitchen use. Such glasses like glass tumblers, glass mugs, whiskey glasses, shot glasses, glass candy jars, glass bowls, beer glasses, etc.

We also recommend the most suitable packaging method based on different sales types, such as different display boxes, adding stickers, tags, etc.