Wine Glasses Manufacturer for Global Brands & B2B Buyers

Mechanically Made & Handcrafted Wine Glasses

OEM / ODM | Factory Direct | Export Worldwide

DM Glassware offer stable quality, flexible customization, and reliable mass production from China.

Are You Looking for a Reliable Wine Glass Supplier?

The same challenges when working on wine glasses projects.

Our Solution — How DM Glassware Solves These Problems

Quality often varies between different production batches, which leads to customer complaints and product return issues.

At DM Glassware, we keep quality stable across different production batches, helping reduce customer complaints and product return issues.

Samples appear acceptable during approval, but mass production quality frequently fails to meet the same expectations.

We produce samples and mass orders using the same specifications to meet approved expectations.

Communication during production is slow or unclear, often causing misunderstandings, delays, and unnecessary follow-ups.

DM Glassware maintain clear and timely communication to prevent misunderstandings, delays, and unnecessary follow-ups.

Logo and packaging customization options are limited, and execution quality is often inconsistent or poorly controlled.

At DM Glassware, we offer flexible logo and packaging customization with well-managed and consistent execution.

Delivery schedules frequently change, especially when placing repeat orders or managing long-term supply programs.

We maintain stable delivery schedules for repeat orders and long-term supply programs.

When quality issues occur, many suppliers avoid responsibility and delay providing clear corrective solutions.

At DM Glassware, we take responsibility and respond quickly with clear corrective solutions.

Check Our Wine Glasses Range

Wine glasses play an important role in how wine is experienced and how a brand is perceived. Shape, size, and design all influence user experience, pricing position, and brand image. For brands and retailers, understanding the differences between wine glass types is key to offering products that align with market expectations and customer preferences.

Wine Glasses by Business Application

Different business models require different wine glass solutions.

Design, durability, cost structure, and supply stability all play an important role in product selection.

We supply wine glasses for a wide range of B2B applications.

Promotional and Corporate Gift Projects

Promotional and corporate gift projects often involve logo customization, special packaging, and specific delivery timelines. These projects may require flexible order quantities and clear execution to meet campaign schedules and branding requirements.

Private Label and E-commerce Brands

Private label and e-commerce brands require wine glasses that stand out in a competitive market. This often includes unique shapes, custom branding, and packaging designed for online sales. Reliable repeat production is essential to ensure consistent customer experience and positive reviews.

Hotels, Restaurants, and Bars

The hospitality industry demands wine glasses that can withstand frequent use and washing while maintaining a consistent look across locations. Durability, balanced weight, and long service life are critical, especially for restaurants and bar chains that reorder regularly.

Wine Brands and Wineries

Wine brands and wineries need wine glasses that reflect brand identity and enhance the tasting experience. Shape, capacity, and clarity play an important role in presenting wine correctly and supporting brand positioning at tastings, events, and retail channels.

Retail and Supermarkets

Retail and supermarket programs focus on stable quality, competitive pricing, and long-term supply consistency. Wine glasses for this channel must perform well in large volumes, maintain uniform appearance across batches, and meet cost targets without sacrificing basic durability or presentation.

Importers and Wholesalers

Importers and wholesalers prioritize stable production capacity, predictable quality, and efficient logistics support. Wine glasses for this channel must be easy to reorder, consistent across shipments, and suitable for distribution to multiple downstream customers.

Mechanically Made vs. Handcrafted Wine Glasses

Wine glasses can be produced using different manufacturing methods, and each method serves different business goals.

Understanding the strengths of mechanically made and handcrafted wine glasses helps B2B buyers choose the right solution based on volume, positioning, and long-term supply strategy.

At DM Glassware, we invest in both production methods to support a wider range of market needs.

Mechanically Made Wine Glasses

High Efficiency, High Consistency, and Scalable Quality

Mechanically made wine glasses are designed for large-volume B2B programs where consistency, efficiency, and repeatability are critical. To expand production capacity and improve manufacturing efficiency, DM Glassware has introduced advanced production lines specifically for mechanically made stemmed wine glasses.

These production lines use core laser cold-cutting technology, which allows precise control of cutting paths and rim finishing. This technology ensures smooth, refined rims and accurate dimensions, achieving a level of quality comparable to handcrafted products.

In addition, we use high-quality crystal-clear flint glass as the base material, resulting in wine glasses with excellent transparency, brightness, and a premium visual appearance.

Key advantages of our mechanically made wine glasses include:

Extremely high consistency across all production batches

Precise control of dimensions, weight, and rim quality

Efficient production speed for large and repeat orders

Cost efficiency for retail, wholesale, and large distribution programs

Stable supply capacity to support long-term product lines

This solution is ideal for brands, supermarkets, importers, and wholesalers that require reliable quality at scale without compromising appearance.

Handcrafted Wine Glasses

Craftsmanship, Design Freedom, and Premium Experience

Handcrafted wine glasses are produced by experienced glass artisans and are best suited for premium, design-driven, and brand-focused projects. This production method allows greater flexibility in shape, bowl design, and overall aesthetics, making it ideal for high-end wine brands and specialty collections.

Each handcrafted wine glass is individually formed, giving it a refined feel and a more organic appearance. This craftsmanship is especially valued in markets where wine tasting experience, presentation, and brand story are key selling points.

Key advantages of our handcrafted wine glasses include:

Greater flexibility in shape, bowl size, and stem design

Refined appearance with a handcrafted feel

Strong appeal for premium and high-end market positioning

Suitable for smaller-volume, high-value product lines

Ideal for wine brands, wineries, and specialty hospitality projects

Handcrafted wine glasses are often chosen when brand differentiation and sensory experience are more important than production volume.

Wine Glass Materials: Soda Lime Glass vs. Lead-Free Crystal

The material of a wine glass plays a critical role in its appearance, weight, durability, and overall drinking experience.

For B2B buyers, choosing the right material also affects cost structure, market positioning, and long-term sales performance.

At DM Glassware, we offer wine glasses made from both soda lime glass and lead-free crystal, helping you select the most suitable material for your target market.

Soda Lime Glass

Practical, Durable, and Cost-Effective

Soda lime glass is the most commonly used material for wine glasses in large-volume B2B programs. It is known for its strength, stability, and cost efficiency, making it suitable for everyday use and high-turnover markets.

Wine glasses made from soda lime glass are designed to perform reliably in retail, hospitality, and wholesale environments where durability and price competitiveness are key considerations.

Key characteristics of soda lime glass wine glasses:

Strong and durable for frequent daily use

Cost-effective for large-volume production

Stable material performance across batches

Suitable for retail, supermarkets, and hospitality programs

Easy to reorder and scale for long-term supply

Soda lime glass is an ideal choice for businesses that prioritize practicality, durability, and consistent supply.

Lead-Free Crystal

Higher Clarity, Refined Feel, and Premium Positioning

Lead-free crystal is a higher-grade glass material designed to enhance visual clarity and drinking experience, without the use of lead. Compared to soda lime glass, lead-free crystal offers better transparency, higher brilliance, and a more refined touch.

Wine glasses made from lead-free crystal are often chosen for premium brands, wine tastings, and high-end hospitality projects where appearance and sensory experience are important.

Key characteristics of lead-free crystal wine glasses:

Higher transparency and brightness

Thinner rims for a smoother drinking experience

More refined appearance and premium feel

Suitable for premium retail and branding projects

Complies with international food safety standards

Lead-free crystal is ideal for brands that want to elevate product perception and offer a more sophisticated wine-drinking experience.

Choosing the Right Material for Your Market

There is no single “best” material — the right choice depends on how the wine glass will be used and sold.

Soda lime glass focuses on durability, cost control, and scalability

Lead-free crystal focuses on clarity, refinement, and premium positioning

At DM Glassware, we help you compare materials based on your business model, target customers, price range, and long-term strategy, ensuring the material choice supports both product performance and market success.

Glass Thickness & Rim Finish

Glass thickness and rim finishing are often overlooked, but they play a critical role in durability, user experience, and overall product positioning.

For B2B buyers, these details directly influence breakage rates, customer feedback, and long-term replacement costs.

At DM Glassware, thickness control and rim finishing are carefully managed to match different usage scenarios and market expectations.

Glass Thickness

Balancing Durability, Weight, and Market Positioning

Glass thickness affects how a wine glass feels in hand, how durable it is during use, and how it performs in real commercial environments.

Thicker glass

Thicker wine glasses offer higher impact resistance and longer service life. They are commonly used in hospitality, high-turnover restaurants, and retail programs where durability and lower breakage rates are critical.Thinner glass

Thinner wine glasses provide a lighter, more refined feel and are often preferred in premium markets. They enhance the drinking experience but require tighter quality control during production and handling.

At DM Glassware, we adjust glass thickness based on product type, material choice, and target application, ensuring the right balance between durability and user experience.

Rim Finish

Smooth Drinking Experience and Consistent Quality

The rim of a wine glass directly affects drinking comfort and perceived quality. Poor rim finishing can negatively impact user experience, even if the glass looks good overall.

We offer different rim finishing methods to meet various market requirements:

Laser cold-cut rim finishing

Provides precise, smooth rims with consistent thickness. This method is commonly used for mechanically made wine glasses and ensures a refined drinking edge comparable to handcrafted products.Fire-polished rim finishing

Creates a smooth and rounded edge through controlled reheating. This method is often used for handcrafted wine glasses and premium designs.

Proper rim finishing improves comfort, reduces sharp edges, and enhances overall product quality perception.

DM Customization Service

Glass cup customization refers to the process of designing and modifying glass cups to meet specific preferences or branding needs. This can include adding logos, artwork, colors, or other personalized elements. Customization allows businesses or individuals to create unique glassware that reflects their identity or message.

Decorations/Laser Engraving

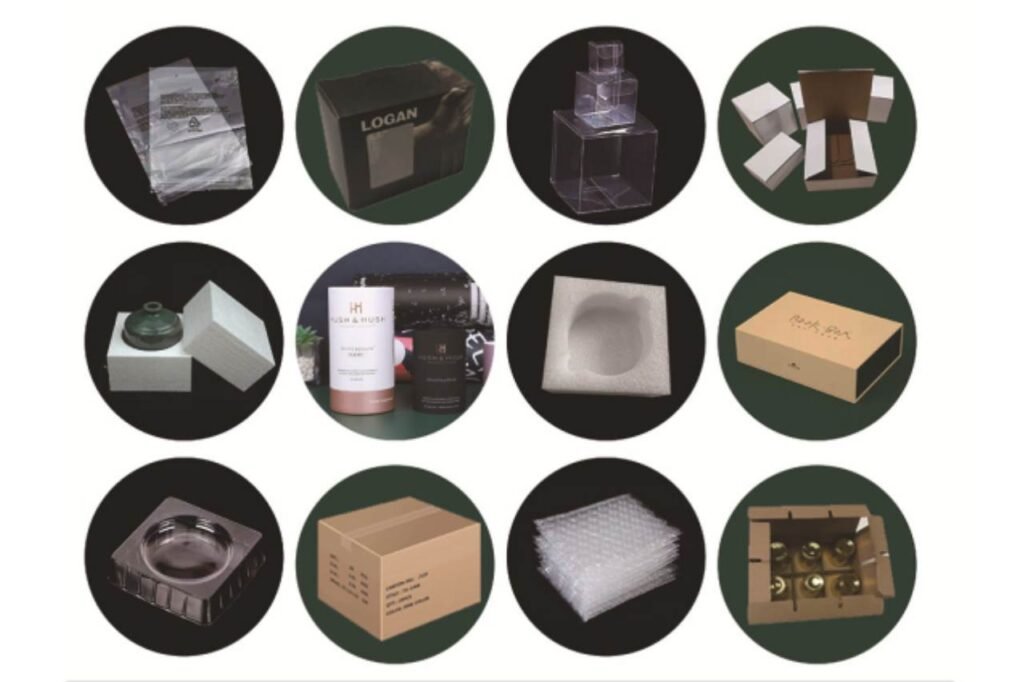

Custom Packagings

Different Glass Cup Shapes and Sizes

Glass cups come in a wide range of shapes and sizes, from tall tumblers to wide mugs. The shape of the glass impacts its usability—tall, slim glasses are great for cocktails, while wide mugs are ideal for hot drinks.

Custom shapes can make the glass stand out and better suit the drink it holds.

Different Color Options and Techniques

Glass cups can be customized with a variety of colors through techniques like painting. Painted glass allows for bold, vibrant hues, while etching adds a frosted, subtle design.

Color choices can be applied to the entire glass or specific areas, such as the rim or base, depending on the desired look.

Logo Placement and Branding

Custom glass cups can be designed with logos and branding elements placed strategically for maximum visibility. The logo can be printed on the side, base, or even wrapped around the glass.

The regular option is using decals.

Engravings, Decals, and Embossing

For a more refined look, businesses can choose engravings, which provide a permanent, elegant design etched directly into the glass.

Decals offer colorful, detailed branding options that can include intricate designs or full-color logos. Embossing raises the design off the surface of the glass, adding texture and a unique tactile element to the glassware.

Quality Control You Can Rely On

Consistent quality is one of the most critical factors in wine glass manufacturing, especially for B2B buyers who require stable supply and repeatable results.

At DM Glassware, quality control is not a single inspection step, but a structured system that runs throughout the entire production process.

Raw Material Selection and Inspection

Quality starts with the material.

We carefully select high-quality raw glass materials based on product requirements, whether soda lime glass or lead-free crystal.

Incoming materials are inspected for clarity, purity, and consistency before entering production, ensuring a stable foundation for every batch.z

In-Process Quality Control During Production

Quality is monitored at every key production stage.

During manufacturing, our quality control team conducts regular in-process inspections to check forming accuracy, wall thickness, weight consistency, and visual appearance.

This allows potential issues to be identified and corrected early, before they affect large quantities.

Appearance, Size, and Thickness Control

Consistency matters for B2B programs.

We apply strict standards for appearance, dimensions, and thickness to ensure each wine glass matches approved samples.

Uniform size and weight help reduce customer complaints, improve packaging efficiency, and ensure consistent user experience across batches.

Pre-Shipment Inspection Before Delivery

Quality checks continue until shipment.

Before delivery, finished wine glasses undergo pre-shipment inspection to confirm product condition, packaging accuracy, and quantity compliance.

This final step helps ensure that products arrive in good condition and meet agreed specifications.

Order Process

DM makes ordering easy and efficient with a clear process from start to finish.

Submit Inquiry

Share your product requirements, specifications, and customization needs with our team.

Receive Quote

Get a detailed proposal and competitive pricing tailored to your needs.

Sample Approval

Review and approve product samples to ensure satisfaction before production.

Shipping

Products are packed securely and shipped to your destination on time.

Quality Inspection

Each product undergoes rigorous testing to meet international standards.

Production

Our team manufactures your products with strict quality control measures.

Related Posts

FAQ

We manufacture a full range of wine glasses, including red wine glasses, white wine glasses, universal wine glasses, stemmed wine glasses, and stemless wine glasses.

Both mechanically made and handcrafted wine glasses are available to meet different market and volume requirements.

We offer wine glasses made from soda lime glass and lead-free crystal.

Soda lime glass is suitable for large-volume, cost-sensitive programs, while lead-free crystal is ideal for premium products that require higher clarity and refined appearance.

Yes. We provide samples for quality and design confirmation before mass production.

Samples are produced using the same materials and processes as bulk orders to ensure consistency.

Sampling typically takes 7–15 days, depending on product complexity and customization level.

Custom molds or special finishes may require additional time.

Mass production usually takes 30–45 days after sample approval.

For repeat orders or standard models, lead time may be shorter depending on production schedule.

Yes. We support full OEM and ODM services, including logo decal, printing, engraving, spray color, and custom packaging such as color boxes and gift boxes.

In many cases, yes.

Mixed models can be arranged depending on production planning and order quantity. Our team will help confirm feasibility during quotation.

We follow the same quality control standards, materials, molds, and production processes for samples and mass orders.

In-process inspections and pre-shipment checks help ensure consistency across batches.

If quality issues occur, we take responsibility.

Our team analyzes the root cause, provides clear feedback, and works with you on corrective solutions to minimize impact and prevent recurrence.

Yes. We export wine glasses to North America, Europe, Australia, the Middle East, and other regions.

We are familiar with international packaging, labeling, and compliance requirements for different markets.

Simply contact our team with your project details.

We will review your requirements, suggest suitable products or solutions, and guide you step by step from sampling to mass production.

Contact Us

DM Glassware is a trusted B2B glassware supplier in China. We offer high-quality, customizable glassware for wholesalers and retailers worldwide.